Mineral Water Cap Making Machine

Detailed Product Description

Features of Mineral Water Cap Making Machine:

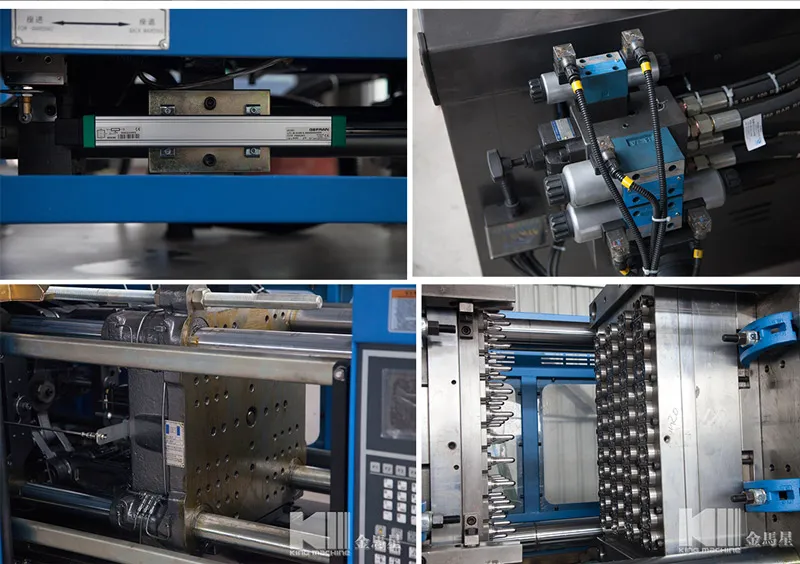

1) LCD computer control with big display screen

2) Hydraulic double proportional valve

3) Hard chrome plated high tensile strength steel tie bars

4) Generous space for fitting large moulds

5) Large opening stroke

6) Two position transducers to control Clamping and Injection

7) Four stages of injecting, independent velocity and pressure control

8) Hydraulic mould height adjustment device

9) Screw cold-start prevention device

10) Melt decompression control

11) Screw back pressure control

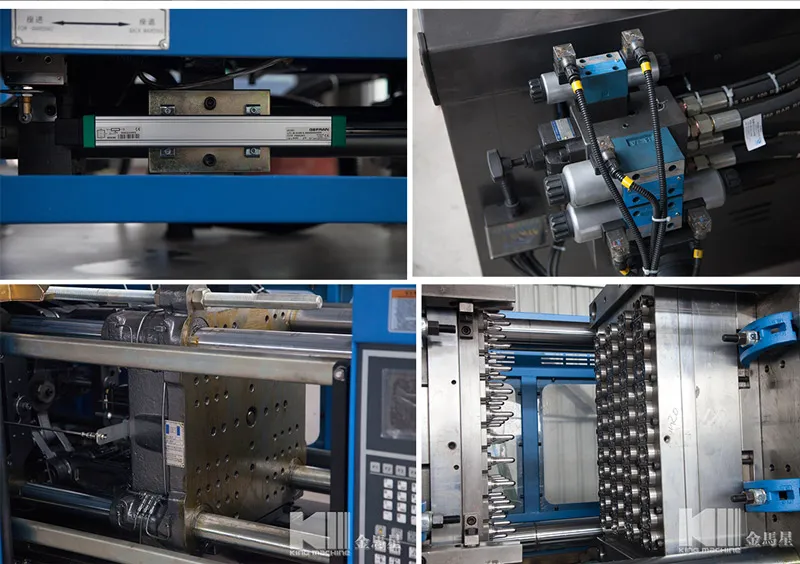

12) Multiple hydraulic ejection

13) Differential high speed clamping

14) Centralized lubrication system

15) Low pressure mould protection device

16) Mechanical safety interlock

17) Double electrical safety interlock

18) Oil return filter

19) Oil tank with inner stainless steel container

| Specification | Clamping force | Max. Plasticising weight(PS)g | Space between tie bars (mm×mm) |

| BST-700A | 70 | 101 | 320×320 |

| BST-950A | 95 | 183 | 360×360 |

| BST-1320A | 130 | 260 | 420×420 |

| BST-1400A | 160 | 486 | 480×480 |

| BST-2000A | 200 | 643 | 505×505 |

| BST-2400A | 240 | 845 | 555×555 |

| BST-3000A | 300 | 1050 | 600×600 |

| BST-3800A | 380 | 1286 | 680×680 |

| BST-4800A | 480 | 1600 | 760×760 |

| BST-5800A | 550 | 2466 | 810×810 |

| BST-6500A | 650 | 2895 | 850×850 |

| BST-7500A | 750 | 3543 | 950×950 |

| BST-10000A | 1000 | 6280 | 1110×1110 |

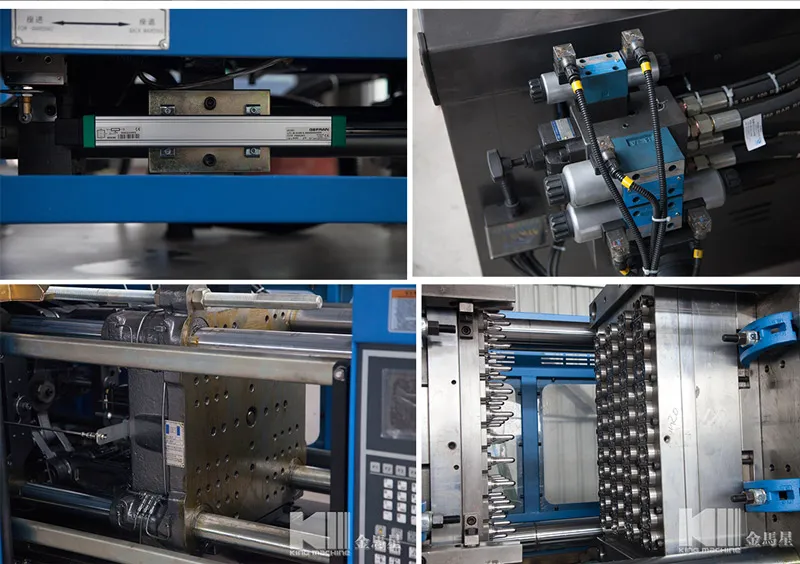

Plastic injection machinery

High Efficiency Energy Saving Injection Molding Machine adopts proportional pressure and flow control, the pressure and the speed can be adjusted, stable movement curve and gentle shock, the computer is imported from Industry family.The LCD displaying screen with high clarity has Chinese and English language to use.Close-loop PID temperature control with the advantage of high precision.The operating table of the injection moulding machine have two safety, one is machine safety, another is electrical safety, that ensures the operators's safety.

Features:

1) LCD computer control with big display screen

2) Hydraulic double proportional valve

3) Hard chrome plated high tensile strength steel tie bars

4) Generous space for fitting large moulds

5) Large opening stroke

6) Two position transducers to control Clamping and Injection

7) Four stages of injecting, independent velocity and pressure control

8) Hydraulic mould height adjustment device

9) Screw cold-start prevention device

10) Melt decompression control

11) Screw back pressure control

12) Multiple hydraulic ejection

13) Differential high speed clamping

14) Centralized lubrication system

15) Low pressure mould protection device

16) Mechanical safety interlock

17) Double electrical safety interlock

18) Oil return filter

19) Oil tank with inner stainless steel container.

| Item | Unit | Data |

| Max. clamping force | KN | 4800 |

| Max. opening distance | mm | 770 |

| Space between tie bars(V×H) | mm | 760×760 |

| Mould height(min-max) | mm | 280-790 |

| Max. daylight | mm | 1560 |

| Ejector force | KN | 113.4 |

| Ejector stroke | mm | 195 |

| Ejector quantity | | 13 |

| Screw diameter | mm | 70 | 75 | 80 |

| Screw L/D ratio | L/D | 22.6 | 21 | 19.7 |

| Theoretical shot volume | cm3 | 1346 | 1545 | 1758 |

| Plasticising weight(PS) | g | 1225 | 1406 | 1600 |

| Injection pressure | Mpa | 201 | 175 | 154 |

| Theoretical injection rate(PS) | g | 370 | 423 | 484 |

| Plasticising capacity(PS) | g/s | 60.4 | 71.4 | 83.7 |

| Screw torque | N.m | 3490 |

| Max. screw rotate speed | r/min | 150 |

| Injection stroke | mm | 350 |

| Carriage push force | KN | 120.6 |

| Pump motor power | KW | 45 |

| Pump pressure | Mpa | 16 |

| Heating power | KW | 28 |

| Heating zone | | 5 |

| Size(L×W×H) | m | 7.5×2.1×2.45 |

| Net weight | t | 20 |

| International designation | | 4800-2710 |

Application : Injection Molding Machine can have a molding complex, the size is accurate or plastic with metal insert of the fine and close texture, are widely used in national defense, electrical, automotive, transportation, building materials, packaging, agriculture, Medical, Household, Appliance sectors and People's Daily life. Today with the rapid development of plastic industry, injection molding machine no matter in quantity or variety occupies an important position.