| Customization: | Available |

|---|---|

| Packaging: | Glass Bottles |

| Automatic Grade: | Automatic |

| Availability: | |

|---|---|

| Quantity: | |

| No. | Device name | Specification model | Quantity | PS. |

| Capping machine spare parts | ||||

| 1.1 | Rubbing belt cover | KMMR5DA-12-27 | 2 | |

| 1.2 | Slip pulley | KMMR5DA-06-28 | 1 | The size of each |

| 1.3 | V-belt | B,L=2692 | 2 | Spare parts |

| 1.4 | Friction block | MR5DA-15-06 | 2 | Spare parts |

| 1.5 | Shake hands | 50-55 | 1 | Tool |

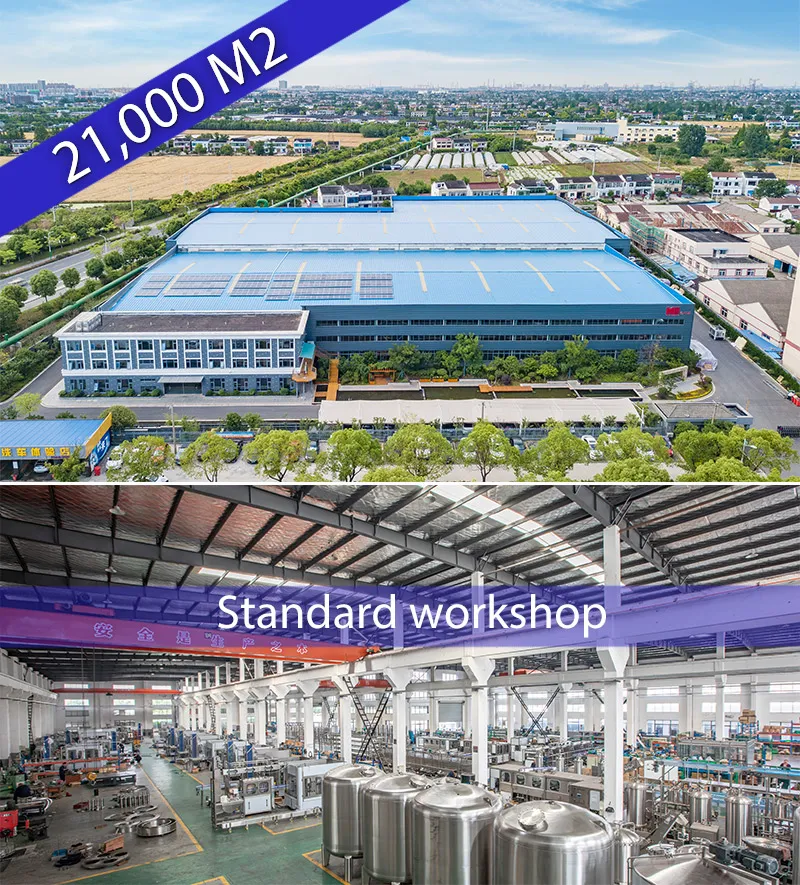

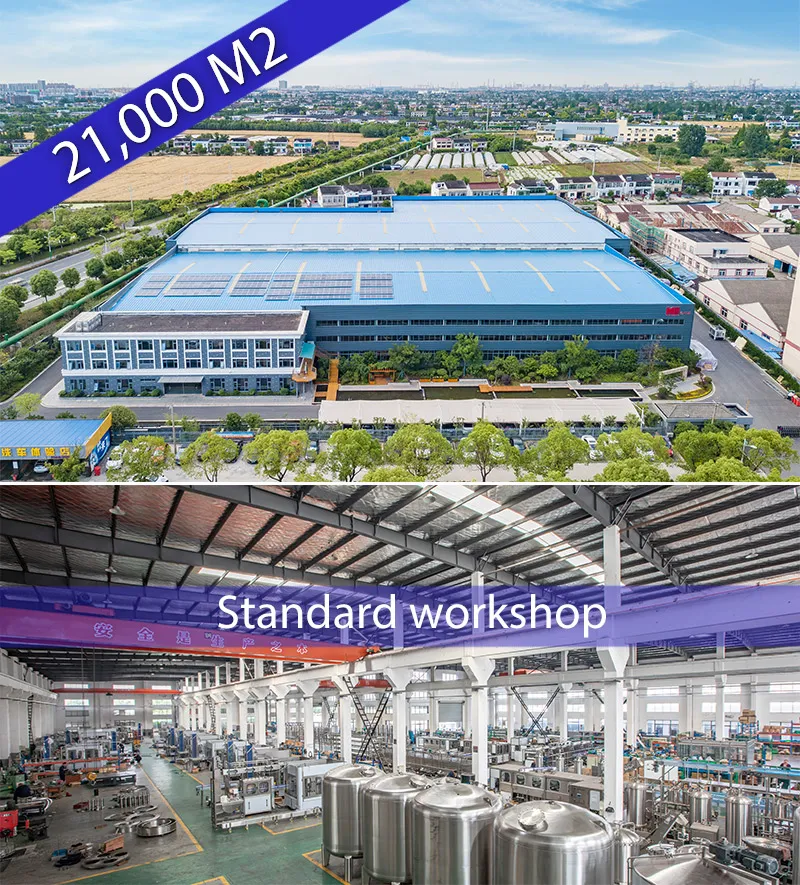

The Pepsi-Cola Second-Hand 24000BPH PET Bottle High-Speed Carbonated Production Line is a premium used solution for beverage producers focused on high-volume carbonated drink manufacturing. Unlike generic second-hand lines, this system was originally built for Pepsi-Cola—meaning it’s engineered to handle the unique demands of carbonated liquids (strict pressure control, airtight sealing, fast filling). With a capacity of 24,000 bottles per hour (bph) for PET bottles, it’s ideal for brands aiming to compete in large markets (supermarkets, convenience stores, food service).

King Machine’s team of engineers fully refurbishes every component: replacing worn parts, testing performance, and calibrating systems to meet new equipment standards. The result is a line that delivers 95% of the performance of new equipment—at a fraction of the cost.

Bottling Capacity: 24,000 bph for 500ml PET bottles. For smaller bottles (200ml), capacity increases to 30,000 bph—flexible for different packaging sizes.

Bottle Dimensions: Accommodates PET bottles with diameter 30–80mm and height 62–260mm. It works with both round and oval PET bottles common in the carbonated drink market.

Carbonation Pressure: Maintains 0.4–0.6MPa during filling, ensuring CO2 stays dissolved in the liquid. This preserves the drink’s fizz and flavor for longer.

Total Power: 12kW (includes filling, capping, conveying, and cooling systems). It uses energy-efficient motors to reduce operational costs.

Steam Pressure: 0.4MPa for the vacuum capping unit, ensuring airtight seals that prevent CO2 leakage.

Machine Dimensions: 12×4×3m (length×width×height), requiring a factory space of at least 50㎡ for installation.

The line’s vacuum capping unit is one of its key features:

Steam Exhausting: Uses steam to remove air from the bottle before capping. This creates a slight vacuum, preventing CO2 loss and extending the drink’s shelf life.

Mechanical Sealing: Equipped with frequency-controlled motors for precise cap torque. It works with screw caps (30–80mm diameter) and reduces defective rates to less than 0.5%.

Stainless Steel Construction: The capping unit is made of SUS304 stainless steel, resisting corrosion from carbonated liquids and meeting food-grade hygiene standards.

This second-hand line is compatible with:

Auxiliary Equipment: King Machine can add new components (labeling machines, carton packers, palletizers) to match your production needs.

Different Carbonated Drinks: Works with cola, soda, sparkling water, and carbonated fruit drinks—no need for major adjustments.

Support services include:

Pre-Delivery Inspection: You can visit King Machine’s factory to test the line before purchase.

Installation & Training: Engineers install the line in 15–20 days and train your team on operation and maintenance.

Spare Parts Supply: King Machine stocks spare parts for the line (rubbing belts, friction blocks, V-belts) to minimize downtime.

For carbonated drink producers looking to scale quickly and affordably, this second-hand line is the perfect choice. It combines proven performance, lower costs, and reliable support.

| No. | Device name | Specification model | Quantity | PS. |

| Capping machine spare parts | ||||

| 1.1 | Rubbing belt cover | KMMR5DA-12-27 | 2 | |

| 1.2 | Slip pulley | KMMR5DA-06-28 | 1 | The size of each |

| 1.3 | V-belt | B,L=2692 | 2 | Spare parts |

| 1.4 | Friction block | MR5DA-15-06 | 2 | Spare parts |

| 1.5 | Shake hands | 50-55 | 1 | Tool |

The Pepsi-Cola Second-Hand 24000BPH PET Bottle High-Speed Carbonated Production Line is a premium used solution for beverage producers focused on high-volume carbonated drink manufacturing. Unlike generic second-hand lines, this system was originally built for Pepsi-Cola—meaning it’s engineered to handle the unique demands of carbonated liquids (strict pressure control, airtight sealing, fast filling). With a capacity of 24,000 bottles per hour (bph) for PET bottles, it’s ideal for brands aiming to compete in large markets (supermarkets, convenience stores, food service).

King Machine’s team of engineers fully refurbishes every component: replacing worn parts, testing performance, and calibrating systems to meet new equipment standards. The result is a line that delivers 95% of the performance of new equipment—at a fraction of the cost.

Bottling Capacity: 24,000 bph for 500ml PET bottles. For smaller bottles (200ml), capacity increases to 30,000 bph—flexible for different packaging sizes.

Bottle Dimensions: Accommodates PET bottles with diameter 30–80mm and height 62–260mm. It works with both round and oval PET bottles common in the carbonated drink market.

Carbonation Pressure: Maintains 0.4–0.6MPa during filling, ensuring CO2 stays dissolved in the liquid. This preserves the drink’s fizz and flavor for longer.

Total Power: 12kW (includes filling, capping, conveying, and cooling systems). It uses energy-efficient motors to reduce operational costs.

Steam Pressure: 0.4MPa for the vacuum capping unit, ensuring airtight seals that prevent CO2 leakage.

Machine Dimensions: 12×4×3m (length×width×height), requiring a factory space of at least 50㎡ for installation.

The line’s vacuum capping unit is one of its key features:

Steam Exhausting: Uses steam to remove air from the bottle before capping. This creates a slight vacuum, preventing CO2 loss and extending the drink’s shelf life.

Mechanical Sealing: Equipped with frequency-controlled motors for precise cap torque. It works with screw caps (30–80mm diameter) and reduces defective rates to less than 0.5%.

Stainless Steel Construction: The capping unit is made of SUS304 stainless steel, resisting corrosion from carbonated liquids and meeting food-grade hygiene standards.

This second-hand line is compatible with:

Auxiliary Equipment: King Machine can add new components (labeling machines, carton packers, palletizers) to match your production needs.

Different Carbonated Drinks: Works with cola, soda, sparkling water, and carbonated fruit drinks—no need for major adjustments.

Support services include:

Pre-Delivery Inspection: You can visit King Machine’s factory to test the line before purchase.

Installation & Training: Engineers install the line in 15–20 days and train your team on operation and maintenance.

Spare Parts Supply: King Machine stocks spare parts for the line (rubbing belts, friction blocks, V-belts) to minimize downtime.

For carbonated drink producers looking to scale quickly and affordably, this second-hand line is the perfect choice. It combines proven performance, lower costs, and reliable support.