| Customization: | Available |

|---|---|

| After-sales Service: | Support |

| Warranty: | 12 Months |

| Availability: | |

|---|---|

| Quantity: | |

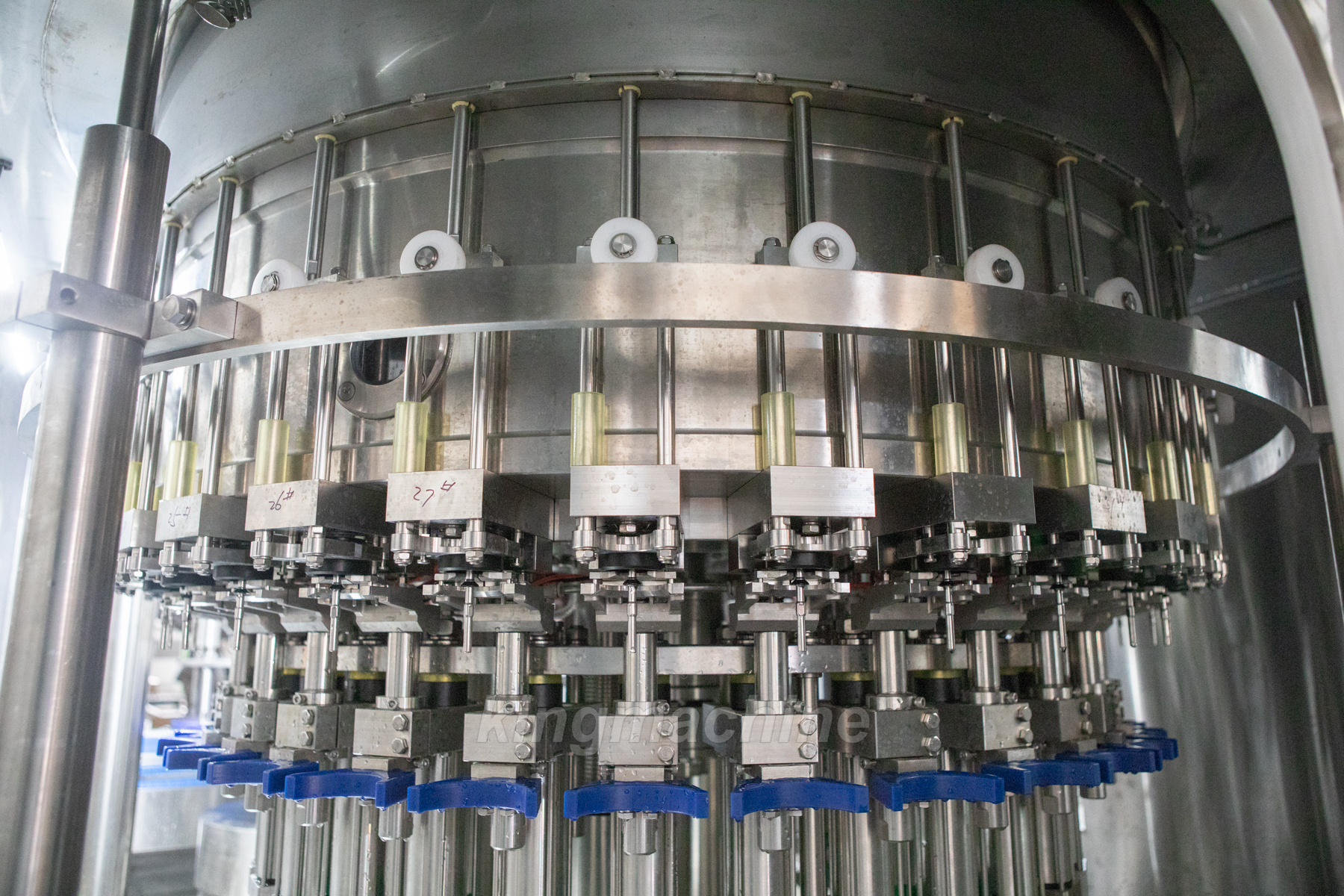

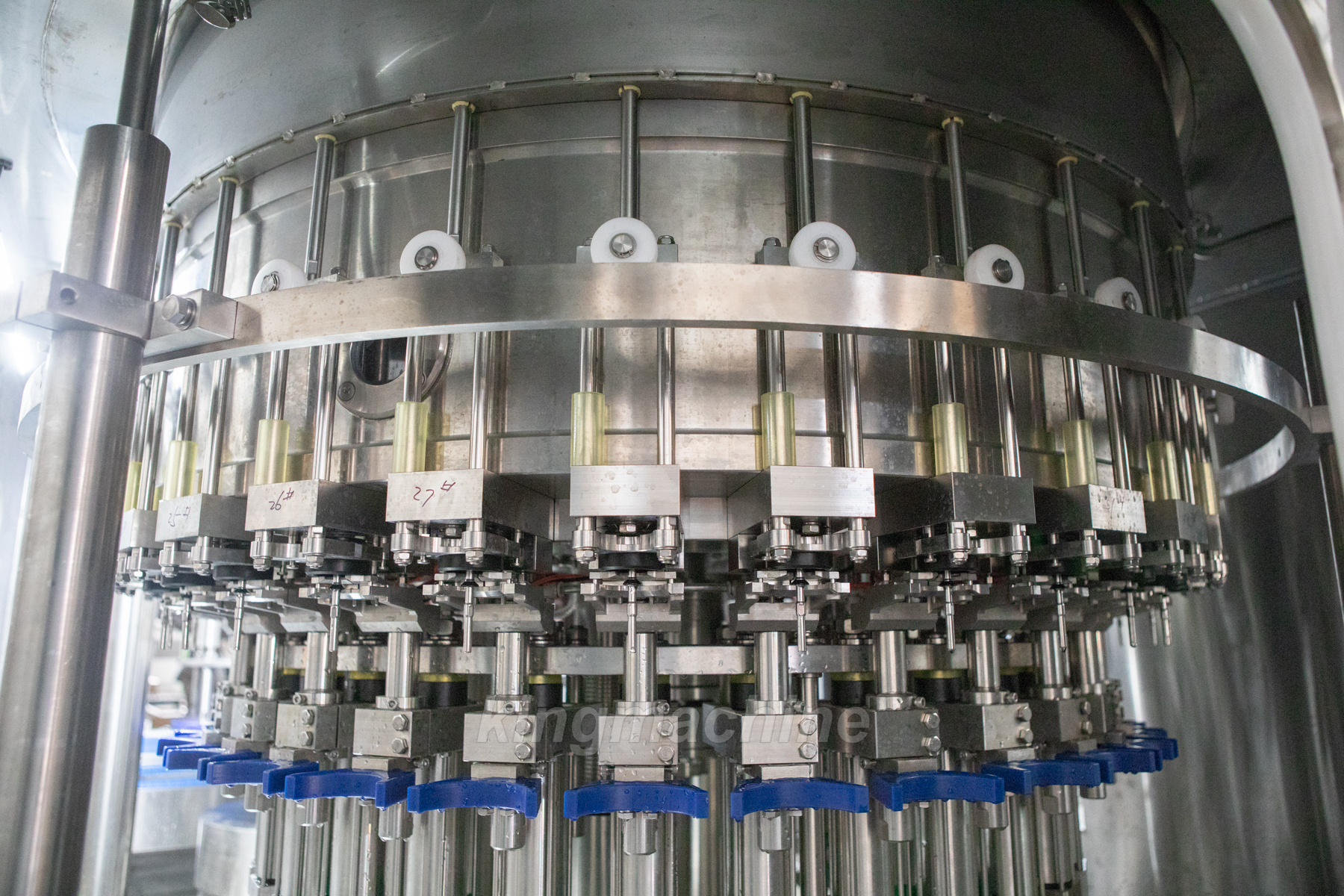

King Machine, a leading manufacturer of beverage packaging machinery based in Zhangjiagang, China, presents its automatic capping machines—a versatile solution designed to streamline bottle sealing processes for small to large-scale businesses. These machines are engineered to handle various cap types, including aluminum caps, crown caps, and sports caps, making them ideal for a wide range of liquid packaging needs.

Equipped with advanced Siemens electrical components and a robust structural design, our automatic capping machines ensure stability, efficiency, and long-term durability. Whether you're packaging bottled water, carbonated drinks, wine, or other beverages, our machines are tailored to meet diverse production demands, with customizable options to fit specific bottle sizes and production volumes. Backed by CE and ISO certifications, these machines adhere to international quality standards, ensuring reliable performance for businesses worldwide.

Our automatic capping machines (Model: KM) boast the following key specifications, optimized for high efficiency and adaptability:

· Material: Constructed from stainless steel 304, ensuring resistance to corrosion, easy cleaning, and compliance with food-grade hygiene standards.

· Production Capacity: Available in multiple configurations, with a range of 1000–25000 bottles/hour to suit small businesses and large-scale production lines alike.

· Power: Operates on 0.5 KW, balancing energy efficiency with consistent performance.

· Bottle Compatibility: Accommodates bottles with a diameter range of Φ60–110mm and height of 140–380mm, making it versatile for various bottle shapes (glass, PET, etc.).

· Dimensions: Customizable based on specific production line layouts, ensuring seamless integration into existing workflows.

· Origin: Manufactured in Zhangjiagang City, China, with strict quality control measures to guarantee reliability.

Our automatic capping machines stand out for their advanced features, designed to enhance productivity and ease of use:

· Advanced Electrical Components: Equipped with Siemens parts, ensuring stable operation and minimal downtime.

· Flexible Cap Compatibility: Specialized models for aluminum caps, crown caps, and sports caps, eliminating the need for multiple machines for different packaging types.

· Customizable Design: Tailored to fit unique production needs, including adjustments for bottle size, cap type, and production speed.

· High Hygiene Standards: Stainless steel 304 construction prevents contamination, making it suitable for food and beverage industries where cleanliness is critical.

· Easy Maintenance: Simplified structure allows for quick cleaning and part replacement, reducing maintenance costs and production interruptions.

· Scalable Production: From small-batch operations (1000 bottles/hour) to high-volume lines (25000 bottles/hour), the machines grow with your business needs.

The automatic capping machines are versatile across multiple industries, with specific applications based on cap type:

· Aluminum Cap Machines: Ideal for sealing glass bottles containing beverages (juices, energy drinks), alcohol (wine, spirits), and condiments, ensuring a tight seal to preserve freshness and prevent leakage.

· Crown Cap Machines: Perfect for carbonated drinks (beer, soda) and bottled water in glass containers, providing a secure seal to maintain carbonation and product quality.

· Sports Cap Machines: Designed for PET bottles used for bottled water, iced tea, and sports drinks, featuring a user-friendly cap design that aligns with on-the-go consumption trends.

Beyond beverages, these machines also cater to industries such as cosmetics, cleaning products, and dairy, where precise and reliable capping is essential for product integrity.

Item | Description | Unit | Model: ACM |

1 | Power | KW | 0.5 |

2 | Main material | / | Stainless steel 304 |

3 | Production capacity | Bottles/hour | 1000–25000 bottle/hour |

4 | Bottle diameter range | / | Φ60–110mm |

5 | Bottle height | mm | 140–380mm |

6 | Dimension | mm | Customized |

7 | Weight | / | N/A |

Whether you're launching a small bottled water business or expanding an existing beverage production line, our automatic capping machines offer the reliability, flexibility, and efficiency needed to streamline operations. Contact us today to discuss custom solutions tailored to your specific needs.

King Machine, a leading manufacturer of beverage packaging machinery based in Zhangjiagang, China, presents its automatic capping machines—a versatile solution designed to streamline bottle sealing processes for small to large-scale businesses. These machines are engineered to handle various cap types, including aluminum caps, crown caps, and sports caps, making them ideal for a wide range of liquid packaging needs.

Equipped with advanced Siemens electrical components and a robust structural design, our automatic capping machines ensure stability, efficiency, and long-term durability. Whether you're packaging bottled water, carbonated drinks, wine, or other beverages, our machines are tailored to meet diverse production demands, with customizable options to fit specific bottle sizes and production volumes. Backed by CE and ISO certifications, these machines adhere to international quality standards, ensuring reliable performance for businesses worldwide.

Our automatic capping machines (Model: KM) boast the following key specifications, optimized for high efficiency and adaptability:

· Material: Constructed from stainless steel 304, ensuring resistance to corrosion, easy cleaning, and compliance with food-grade hygiene standards.

· Production Capacity: Available in multiple configurations, with a range of 1000–25000 bottles/hour to suit small businesses and large-scale production lines alike.

· Power: Operates on 0.5 KW, balancing energy efficiency with consistent performance.

· Bottle Compatibility: Accommodates bottles with a diameter range of Φ60–110mm and height of 140–380mm, making it versatile for various bottle shapes (glass, PET, etc.).

· Dimensions: Customizable based on specific production line layouts, ensuring seamless integration into existing workflows.

· Origin: Manufactured in Zhangjiagang City, China, with strict quality control measures to guarantee reliability.

Our automatic capping machines stand out for their advanced features, designed to enhance productivity and ease of use:

· Advanced Electrical Components: Equipped with Siemens parts, ensuring stable operation and minimal downtime.

· Flexible Cap Compatibility: Specialized models for aluminum caps, crown caps, and sports caps, eliminating the need for multiple machines for different packaging types.

· Customizable Design: Tailored to fit unique production needs, including adjustments for bottle size, cap type, and production speed.

· High Hygiene Standards: Stainless steel 304 construction prevents contamination, making it suitable for food and beverage industries where cleanliness is critical.

· Easy Maintenance: Simplified structure allows for quick cleaning and part replacement, reducing maintenance costs and production interruptions.

· Scalable Production: From small-batch operations (1000 bottles/hour) to high-volume lines (25000 bottles/hour), the machines grow with your business needs.

The automatic capping machines are versatile across multiple industries, with specific applications based on cap type:

· Aluminum Cap Machines: Ideal for sealing glass bottles containing beverages (juices, energy drinks), alcohol (wine, spirits), and condiments, ensuring a tight seal to preserve freshness and prevent leakage.

· Crown Cap Machines: Perfect for carbonated drinks (beer, soda) and bottled water in glass containers, providing a secure seal to maintain carbonation and product quality.

· Sports Cap Machines: Designed for PET bottles used for bottled water, iced tea, and sports drinks, featuring a user-friendly cap design that aligns with on-the-go consumption trends.

Beyond beverages, these machines also cater to industries such as cosmetics, cleaning products, and dairy, where precise and reliable capping is essential for product integrity.

Item | Description | Unit | Model: ACM |

1 | Power | KW | 0.5 |

2 | Main material | / | Stainless steel 304 |

3 | Production capacity | Bottles/hour | 1000–25000 bottle/hour |

4 | Bottle diameter range | / | Φ60–110mm |

5 | Bottle height | mm | 140–380mm |

6 | Dimension | mm | Customized |

7 | Weight | / | N/A |

Whether you're launching a small bottled water business or expanding an existing beverage production line, our automatic capping machines offer the reliability, flexibility, and efficiency needed to streamline operations. Contact us today to discuss custom solutions tailored to your specific needs.