Views: 0 Author: Site Editor Publish Time: 2025-01-23 Origin: Site

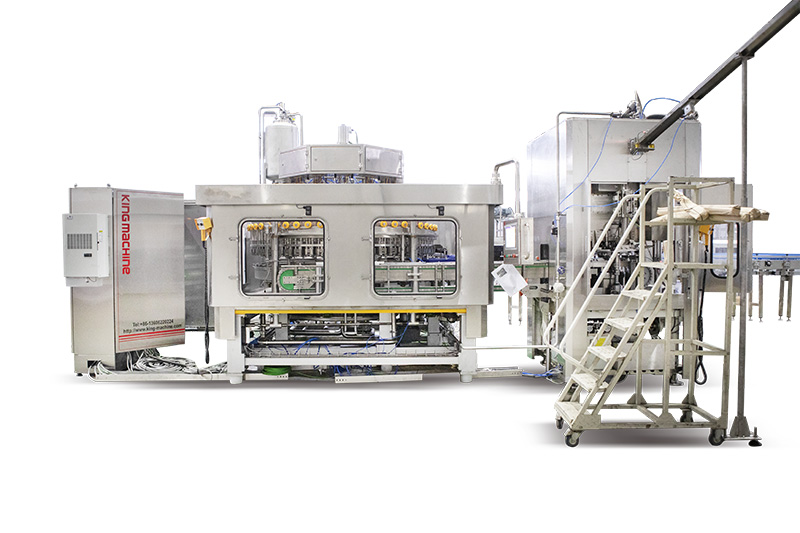

Beverage filling machines are crucial to modern beverage production, ensuring high-speed, precise filling of bottles, cans, and other containers. Whether it's water, juice, or carbonated beverages, these machines are designed to handle a variety of production needs. The continuous advancements in filling technology have made these machines more reliable, versatile, and energy-efficient.

The integration of automation in beverage filling machines has enhanced their speed and precision. Automation allows these machines to fill containers consistently and at higher speeds, reducing human error. Advanced sensors ensure that each container is filled to the correct level, and the production line operates with minimal downtime. This ability to handle different bottle sizes and types with precision boosts overall efficiency. For example, Flowmeter filling monoblock and Gravity filling monoblock systems are commonly used to achieve consistent fills with minimal variation.

As sustainability becomes more important, beverage filling machines are evolving to be more energy-efficient. New features, such as variable frequency drives and energy-saving pumps, reduce energy consumption, helping manufacturers meet sustainability goals while improving the bottom line. Technologies like electronic volumetric filling monoblocks and Isobaric filling monoblock further enhance efficiency without sacrificing performance.

One significant advantage of modern beverage filling machines is their ability to adapt to various types of beverages. These machines can handle still and carbonated drinks and hot or cold filling products, allowing manufacturers to diversify their product lines. The flexibility to quickly switch between beverage types on the same line makes production more efficient and versatile. Machines like Piston Filling Monoblock, Float-ball cylinder type volumetric filling, and high-speed filling valve enable smooth transitions and precise fills, whether the product is still or carbonated.

Maintaining high product quality is a top priority for beverage manufacturers. The latest filling technology in beverage filling machines ensures that each product meets stringent quality standards. With advanced sensors and monitoring systems, these machines detect any discrepancies and provide real-time feedback to operators, ensuring that every bottle is filled accurately. Features such as the Electronic weight filler and Isobaric filling valve help to ensure consistent fill levels, even for products that require precise carbonation.

Beverage filling machines are essential in today’s beverage industry. With advances in automation, energy efficiency, and flexibility, they continue to revolutionize beverage production by improving both speed and product quality. The use of technologies like Mechanical Filling Valve, Negative pressure filling valves, and juice fillers will keep evolving to meet the growing demands for higher quality and lower energy consumption in the industry.