Views: 0 Author: Site Editor Publish Time: 2025-01-30 Origin: Site

Ultra hygienic monoblocks are revolutionizing beverage manufacturing by ensuring that products are produced in the most sanitary environments. Combining multiple processes such as filling, capping, and sterilization into a single unit, these machines offer enhanced hygiene control and efficient production.

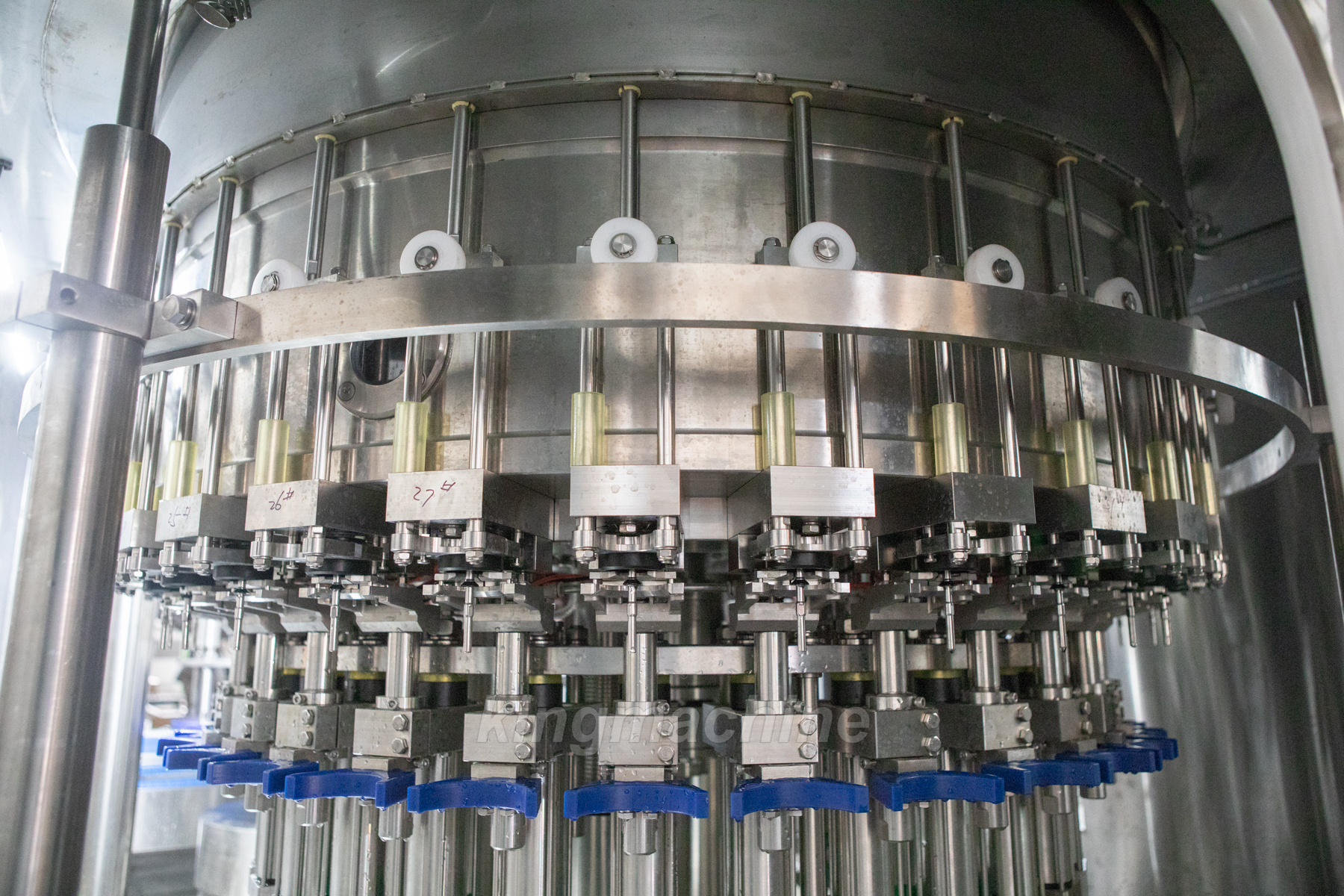

An Ultra hygienic monoblock integrates various production steps, reducing the risk of contamination. These machines are designed with easy-to-clean surfaces and advanced features like automated CIP (cleaning in place) systems, making them ideal for ensuring food safety. Ultra Hygienic Filling Machines and Ultra Hygienic Filler systems ensure that each step of the production process maintains the highest hygiene standards.

With built-in sterilization systems, these machines ensure that the beverage is free from bacteria and contaminants. Sterilization capabilities such as automated cleaning and sanitization of the machine help prevent microbial contamination, maintaining product quality.

By combining multiple production processes into one unit, monoblocks help reduce capital costs and space requirements. Additionally, they increase efficiency by reducing the time needed for transfer between machines, which leads to cost savings.

Ultra hygienic monoblocks contribute to sustainability goals by improving energy efficiency and reducing waste. The efficient cleaning systems also reduce the need for chemical usage, contributing to more eco-friendly production practices.

Ultra hygienic monoblocks contribute to sustainability goals by improving energy efficiency and reducing waste. The efficient cleaning systems also reduce the need for chemical usage, contributing to more eco-friendly production practices. With Ultra Hygienic Filler systems, beverage manufacturers can also lower their environmental footprint.

The Essential Role of Ultra Hygienic Monoblocks in Modern Beverage Manufacturing

In the modern beverage industry, Ultra Hygienic Monoblocks are essential for maintaining high standards of hygiene, efficiency, and sustainability. Their integration of multiple processes in one unit makes them a critical part of beverage production.