Views: 0 Author: Site Editor Publish Time: 2025-11-10 Origin: Site

When KOMOS, one of Russia’s top dairy manufacturers, planned to upgrade its Kazan production base, the company faced a serious challenge:

the ceiling height was too low to install a standard rotary bottle blowing machine.

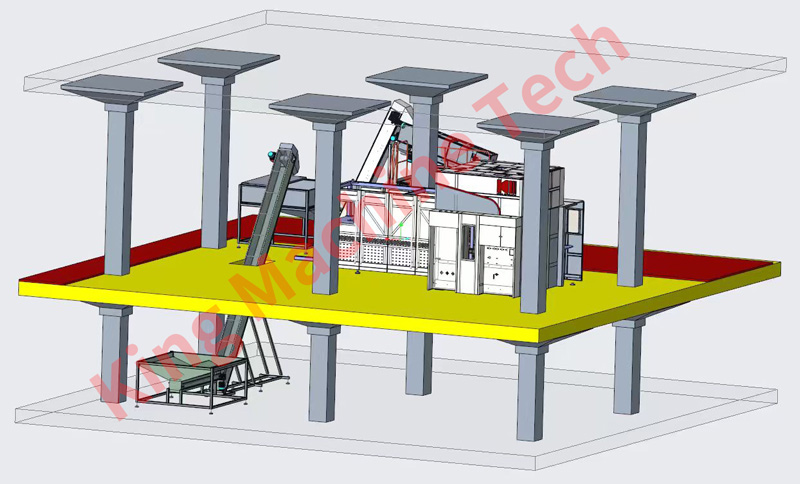

King Machine Company took up the challenge by providing a custom 3D engineering design and reconfiguring the machine layout across

different floor levels. The bottle blowing machine was placed on the lower floor, while the air conveyor was installed above,

connecting the blowing system to the filling area.

This multi-level installation solution not only overcame the height restriction but also maintained high production efficiency and bottle flow stability.

The suspended air conveyor design was carefully calculated for load balance and vibration control, ensuring reliable operation in the long run.

Thanks to King Machine’s 3D modeling system, the project was executed smoothly from concept to commissioning. The cooperation between

King Machine and KOMOS demonstrates the company’s strong ability to provide customized bottle blowing and air conveyor solutions

tailored to different factory structures.

Keywords: King Machine Company, rotary bottle blowing machine, air conveyor system, 3D factory layout, bottle blowing line,

customized engineering solution, Russia KOMOS.