Views: 0 Author: Site Editor Publish Time: 2025-06-06 Origin: Site

Water filling machines are essential for industries that require precise and efficient liquid packaging. Whether you're a manufacturer, business owner, or engineer, this guide will help you understand the various types of filling machines available. We'll cover everything from choosing the right machine to installation and maintenance to ensure optimal performance for your production needs.

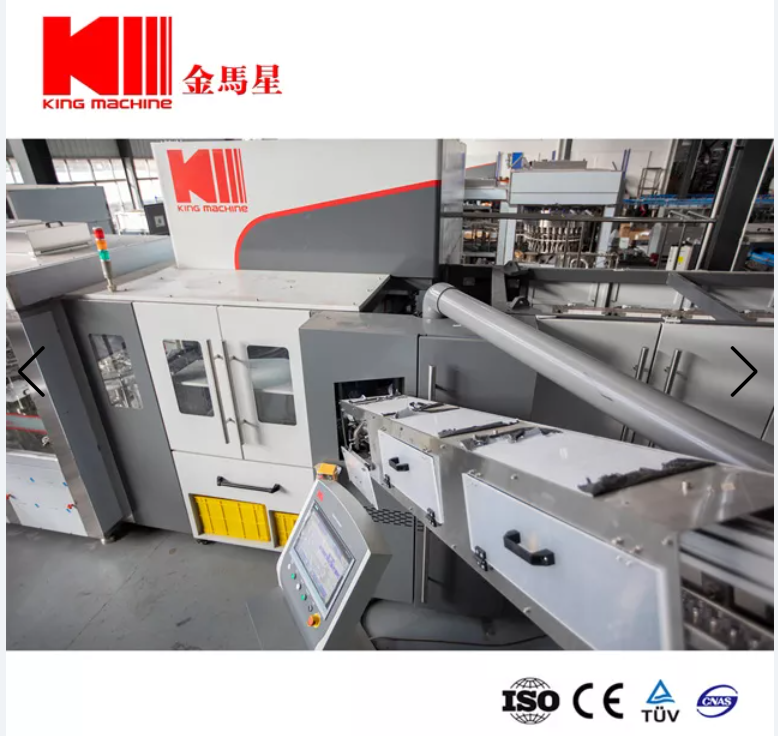

A water filling machine is an automated system designed to fill containers with water at a precise volume. It plays a key role in bottling plants, ensuring quick, efficient, and hygienic filling of bottles. These machines help businesses meet high demand while maintaining product consistency.

Water filling machines are used across industries such as bottled water production, beverages, and food processing. In these sectors, they ensure the safe and efficient packaging of liquid products. By automating the process, they reduce labor costs and improve overall production efficiency.

Key benefits include enhanced efficiency, accuracy, and consistency. Water filling machines eliminate human error, ensuring that each bottle receives the same volume of water, every time. This leads to faster production rates and higher product quality.

The filling system is responsible for dispensing water into bottles. There are several types of systems:

● Volumetric Filling: Measures and fills based on the volume of water.

● Gravimetric Filling: Uses weight to determine the correct amount of water.

● Piston-Based Systems: Ideal for handling thicker liquids or those with more variation in flow.

Each system is designed to ensure the precise filling of bottles with minimal wastage.

Once filled, bottles must be sealed to prevent contamination. The capping system is essential for ensuring that caps are tightly secured. A well-functioning capping system minimizes spillage and prevents leaks during transportation.

The conveyor system is responsible for moving bottles through the production line. It guides bottles from one station to another, from filling to capping and labeling. By reducing human intervention, the conveyor system boosts speed and minimizes errors.

The control system is the brain of the water filling machine. It automates and regulates the entire filling process, including filling, capping, and labeling. This system ensures all components work together smoothly and efficiently, allowing for precise control over each stage of production.

Automatic water filling machines are designed for large-scale production. They handle high volumes of bottles, requiring minimal human intervention. These systems can fill thousands of bottles per hour, making them ideal for businesses with high production demands.

Semi-automatic machines require some manual involvement. Operators still need to place bottles, but the filling process is automated. These machines offer a balance of speed and flexibility, making them perfect for medium-sized operations.

Manual water filling machines are the most basic. These require full human control for each bottle. Although they’re slow and labor-intensive, they work well for small-scale operations or businesses testing new products.

Gravity fillers use the natural force of gravity to fill bottles. They are most effective for thin liquids like water, offering an affordable and simple solution for filling large quantities.

Pressure fillers are designed for higher viscosity liquids. They use pressure to push the liquid into containers, ensuring a consistent fill. These machines are suited for liquids that flow more slowly or have varying densities.

Vacuum fillers are ideal for preserving water quality. They reduce air in the container while filling, which helps maintain the integrity of the product. This method is commonly used in delicate bottling processes.

Consider the scale of your operation. If you need high output, automatic machines are ideal. For smaller production runs, semi-automatic or manual machines may be more suitable.

Make sure the machine can handle the bottle size and shape you use. Some machines are adjustable, while others are specialized for specific bottle types.

Water filling machines must meet sanitation standards. Look for machines with sterilization features to ensure hygiene, especially in food and beverage industries.

Choose machines that balance performance and energy usage. This ensures long-term cost-effectiveness and reduces the operational cost of your filling line.

Some businesses need filling machines that can handle different bottle sizes. Look for machines with customizable settings to accommodate your specific production needs.

The production volume is one of the most critical factors when choosing a water filling machine. High-output businesses should look for automatic machines, which can fill thousands of bottles per hour. For medium-scale operations, semi-automatic systems may suffice, while manual machines are better suited for smaller production lines.

Choose a machine that fits the size and shape of your bottles. Some machines are adjustable, allowing you to handle a variety of bottle sizes. Be sure the machine can accommodate your packaging design, whether it’s wide, narrow, or unique shapes.

Water quality is vital in industries like food and beverage. Look for machines with sterilization features to meet hygiene standards. Machines designed for food-grade standards ensure that your water is packaged in clean, contamination-free conditions.

Energy efficiency is crucial for keeping operational costs low. Evaluate the energy consumption of the machines and opt for one that provides high performance while consuming less energy. Machines with energy-saving features can significantly reduce long-term costs.

Some businesses require machines that can handle multiple bottle sizes or specific filling requirements. It’s important to choose a water filling machine that can be customized to suit your unique production needs. Machines with adjustable settings provide flexibility and help accommodate growth.

Before installing your water filling machine, ensure your production area is ready. Verify that the space is adequate and all utility connections (water, electricity, and compressed air) are in place. This helps streamline the installation process and avoid delays.

Position the machine strategically on your production line. Proper placement ensures smooth integration with other equipment, such as conveyors, capping machines, and labeling systems. The setup should allow for easy access to maintenance points and efficient workflow.

Calibrate the machine to ensure it meets your specific production needs. Set the correct filling volume, pressure, and other parameters to guarantee accurate and consistent filling. Regular calibration helps prevent errors and ensures the system performs as expected.

After installation and calibration, run initial tests. These tests verify that the machine functions properly and meets your production specifications. Ensure the system runs smoothly and identifies any issues before the machine is used for full-scale production.

Step | Description |

Preparation | Ensure proper utility connections are available. |

Placement and Setup | Position the machine on the production line. |

Calibration | Set the right filling volume, pressure, etc. |

Testing | Run tests to check machine functionality. |

When manufacturing bottled water, it’s essential to ensure that your water filling machines comply with regulatory standards. The FDA (Food and Drug Administration) and GMP (Good Manufacturing Practice) guidelines are critical to ensure the safety and quality of bottled water. These regulations help ensure that your equipment meets hygiene, performance, and safety standards for the food and beverage industry.

Water filling machines must adhere to local and international water quality standards such as NSF (National Sanitation Foundation) and ISO (International Organization for Standardization). These certifications guarantee that the water filling process is safe and that the water itself meets the purity and safety requirements expected by consumers.

Safety is a top priority for both workers and the equipment itself. Water filling machines must comply with safety regulations to ensure that operators are not exposed to hazardous situations. This includes adhering to electrical safety standards, emergency shutdown protocols, and maintaining equipment to prevent malfunctions or accidents during production.

Automated water filling machines significantly boost production speed, allowing manufacturers to fill more bottles in less time. Automation reduces the need for manual labor, cutting down on human errors and improving overall efficiency on the production line.

Automated systems ensure that each bottle is filled to the exact level every time. This consistency reduces waste and ensures that all products meet the same quality standards. No more uneven fills, meaning fewer chances of consumer complaints or product recalls.

By reducing the need for manual labor, automated machines help cut labor costs. Additionally, their ability to run continuously at high speeds increases production capacity without needing to hire more workers, making the process more cost-effective.

Automated systems are designed to integrate seamlessly with quality control processes. This ensures that the quality of the water remains consistent throughout the filling process. From the precise measurement of each bottle to the high-speed production, automation helps maintain high product standards.

Benefit | Description |

Increased Efficiency | Speeds up production and reduces labor needs. |

Consistency | Ensures each bottle is filled to the exact level. |

Cost-Effectiveness | Reduces labor costs and boosts production capacity. |

Product Quality Control | Maintains high product standards throughout the process. |

Choosing the right water filling machine is crucial for your business’s success. It impacts efficiency, consistency, and product quality. Regular maintenance ensures smooth operation and reduces downtime, keeping production running smoothly. For the best results, consult experts during machine selection and installation. This ensures optimal performance and long-term productivity.

A: Automatic water filling machines are fully automated and designed for high-speed, large-scale production, while semi-automatic machines require some manual input and are suitable for smaller operations.

A: Consider your production volume, bottle size, water quality requirements, and budget to determine the appropriate machine for your business.

A: Yes, some machines are adjustable and can handle multiple bottle sizes, but others may need customization or specific parts.

A: The lifespan varies but regular maintenance can extend the life of your machine to 10-15 years or more.

A: Ensure your machine meets FDA, GMP, and water quality certifications like NSF or ISO, and follow local regulations for safety and hygiene.