Views: 0 Author: Site Editor Publish Time: 2025-06-04 Origin: Site

Installing a water filling line correctly is crucial for efficient production and product quality. Industries like bottled water, food processing, and beverages rely on these systems for high-volume production.

In this post, we'll guide you through each step of installing a water filling line, from setup to final installation. Learn how to ensure proper installation, meet industry standards, and avoid common issues.

A water filling line is a system designed for efficiently filling bottles or containers with water or other liquid products. It plays a key role in industries like bottled water production, food processing, and beverage manufacturing.

The main functions of a water filling line include:

● Filling: Accurately dispensing the correct amount of liquid into containers.

● Capping: Sealing the containers to prevent leakage and contamination.

● Labeling: Applying labels to the containers for product identification.

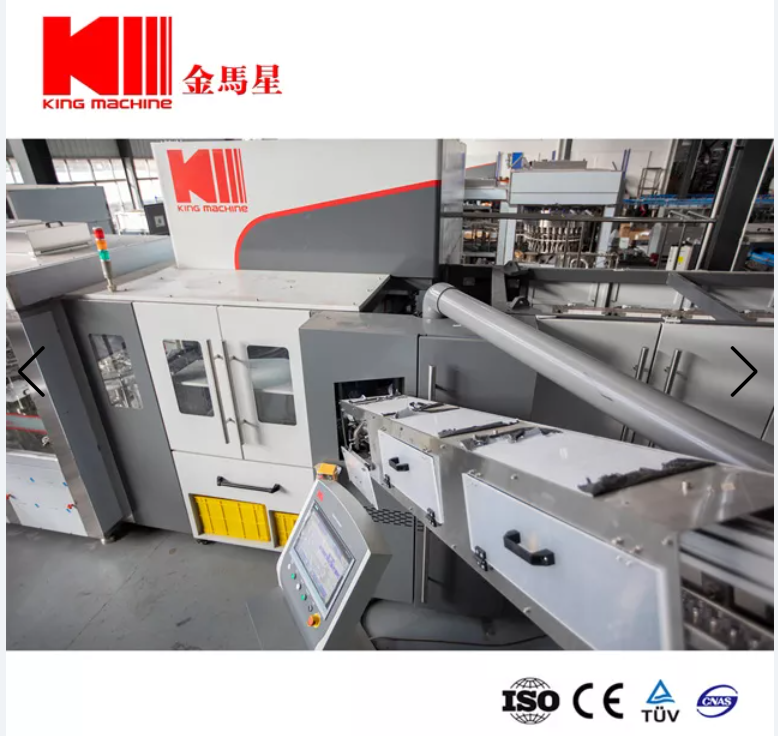

Key components of a water filling line include the filling machine, capping machine, conveyor system, and labeling equipment. These components work together to ensure high-speed, accurate production.

Setting up a water filling line requires several essential tools and equipment. Here’s a breakdown:

● Plumbing Materials: Use stainless steel or NSF-certified plastic tubing for piping. Ensure the pipes are resistant to corrosion and capable of handling the machine’s pressure.

● Filling Equipment: The installation requires filling machines, pumps, and valves. Choose equipment based on your production scale and container sizes.

● Electrical Setup: Ensure a reliable power source for all machines. Electrical systems must meet the specifications of the equipment to prevent malfunctions.

● Utilities Setup: Install water supply lines, air supply systems, and compressed air connections to ensure smooth operation.

● Installation Safety Tools: Use appropriate safety equipment, including gloves, goggles, and lockout tools, to ensure a safe installation process.

By having the right tools and equipment, the installation process becomes more efficient and ensures the water filling line operates smoothly.

Before installation begins, take time to plan and prepare. Here’s what to consider:

Step | Action |

Evaluate Production Needs | Define your production goals (bottle sizes, production rate). |

Design the Factory Layout | Plan the space to ensure a smooth workflow between machines. |

Check Utilities Availability | Confirm access to water, electricity, and compressed air. |

Correct plumbing installation ensures your water filling line operates without interruptions. Follow these steps:

Step | Action |

Material Selection | Use food-grade, corrosion-resistant materials like stainless steel or NSF-certified plastics. |

Sizing the Pipes | Choose pipe sizes that match the machine’s capacity to ensure proper flow. |

Valve Installation | Install isolation valves at key points to control water flow. |

Drainage Setup | Set up drainage systems for wastewater management (soakaway, sewer, surface runoff). |

Proper water treatment ensures the water quality meets industry standards:

Step | Action |

Water Quality Assessment | Test incoming water for contaminants like sediment, chlorine, and microorganisms. |

Filtration and Treatment | Choose the right filtration (e.g., reverse osmosis, carbon filters) based on water quality. |

Flow Rate and Capacity | Ensure the treatment system handles the machine’s flow rate and includes a safety margin. |

Now, it’s time to install your filling and capping machines:

Step | Action |

Machine Placement | Position machines according to your factory layout for a smooth workflow. |

Calibration | Calibrate each machine for precise filling, capping, and labeling. |

Integration with Conveyor System | Connect machines to a conveyor system for seamless bottle movement. |

Electrical and mechanical setup is crucial for smooth operation:

Step | Action |

Electrical Wiring | Properly wire machines to the electrical supply and secure all connections. |

Mechanical Safety | Install safety guards and interlocks to prevent accidents. |

Once everything is set up, it’s time to test the system:

Step | Action |

Initial Test Run | Run test batches to identify issues in the setup (fill volumes, machine performance). |

Leak Testing | Inspect plumbing and filling systems for leaks to avoid wastage and contamination. |

Performance Validation | Test fill volumes, capping, and labeling accuracy. Adjust as needed to ensure smooth operation. |

During installation, you may encounter several common issues. Here's how to address them:

Leaks in the water and air supply lines can disrupt the entire production line. Here’s how to fix them:

● Identification: Check for visible water drips or unusual pressure drops in the system.

● Fixing Leaks: Tighten any loose fittings or replace damaged seals. Ensure that all connections are properly secured.

Improper machine calibration can lead to inaccurate fill levels, affecting product consistency. To fix this:

● Adjust the Settings: Refer to the machine’s manual for the proper calibration procedure.

● Test and Adjust: Run test batches and adjust the settings until the fill levels are consistent across all containers.

Electrical malfunctions can disrupt the entire system. Common issues include:

● Power Surges: Ensure the power supply meets the voltage requirements of the machines.

● Wiring Problems: Inspect all wiring connections for any loose or disconnected wires and correct them.

Once the water filling line is installed, regular maintenance is crucial for smooth operation. Here are some best practices:

Task | Action |

Regular Cleaning | Clean machines regularly to prevent contamination and maintain hygiene. |

Routine Maintenance | Inspect pipes, machines, and valves regularly to prevent breakdowns and improve longevity. |

Flushing Program | Implement a flushing program to ensure the water supply remains clean and fresh, preventing bacterial growth. |

Routine checks, cleaning, and maintenance will keep the system running efficiently and reduce the risk of operational issues.

When installing a water filling line, it's crucial to adhere to various regulatory standards to ensure product safety, quality, and employee protection. Here’s what you need to know:

Water filling lines must comply with both local and international standards to meet industry guidelines. Some common regulations include:

● FDA: Ensures that the water filling process follows food safety and hygiene standards.

● GMP: Good Manufacturing Practices, which ensure consistency, quality, and safety in water production.

● NSF: National Sanitation Foundation standards ensure the materials used in the system are safe and suitable for food-grade production.

Regular testing is necessary to ensure the water used in the filling process is safe for consumption. Testing should include:

● Microbial Testing: Check for contaminants like bacteria and viruses.

● Chemical Testing: Assess the water for harmful chemicals or minerals.

● Physical Testing: Test turbidity, color, and odor to ensure the water meets the required standards.

Adhering to safety guidelines is essential during both installation and operation of the water filling line. Follow these protocols:

● Personal Protective Equipment (PPE): Ensure all workers are equipped with the proper safety gear, such as gloves, goggles, and protective clothing.

● Machine Safeguarding: Install safety guards and emergency stop buttons to prevent accidents.

● Training: Provide proper training for workers to handle equipment safely and respond to emergencies.

Following these regulations and guidelines ensures that your water filling line operates efficiently, safely, and within legal standards.

Installing a water filling line correctly is essential for smooth operation and product quality.

Ensure proper planning, setup, and testing to achieve high-efficiency production.

Follow each step carefully and consult professionals for guidance during installation to avoid issues.

A: A water filling line includes a filling machine, capping machine, labeling machine, and conveyor system.

A: Installation time varies depending on system complexity, ranging from a few days to several weeks.

A: Food-grade stainless steel or NSF-certified plastic tubing is recommended for durability and safety.

A: Yes, modern filling lines are adjustable and can accommodate various container sizes with the right settings.

A: Regular cleaning, equipment inspections, and implementing a flushing program are essential for maintenance.