Views: 0 Author: Site Editor Publish Time: 2025-06-03 Origin: Site

Liquid filling production lines are essential in various industries, ensuring precise and efficient packaging. With automation, these systems reduce human error, boost speed, and maintain consistency.

In this post, we'll explore the key components of a basic liquid fill production line, from filling machines to labeling systems. Learn how each part works together to streamline operations and improve overall efficiency.

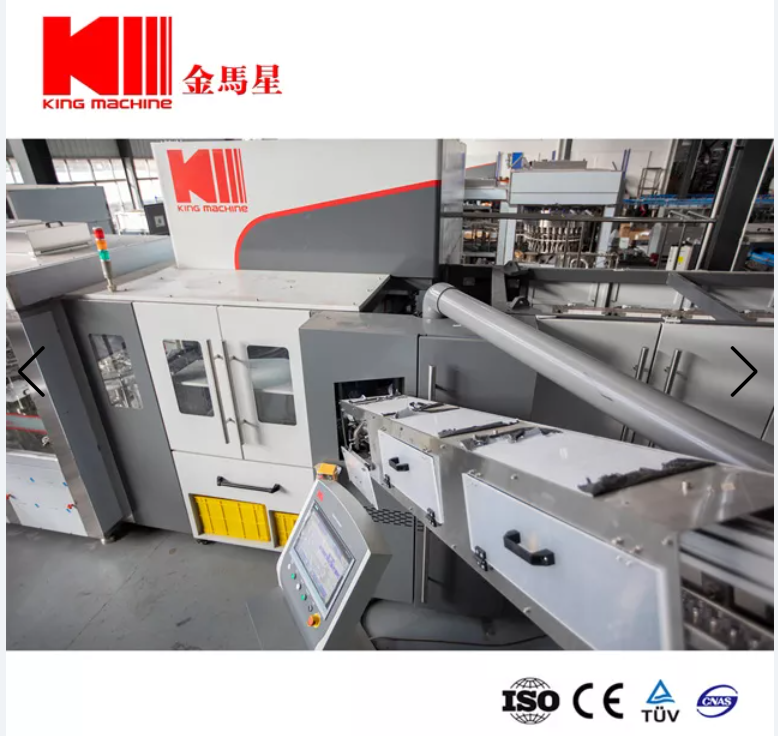

A liquid fill production line is a system designed to automate the process of filling containers with liquid products. It is used in various industries to ensure products are filled accurately and efficiently, while maintaining product quality and consistency.

Liquid filling lines are essential in industries like food and beverage, pharmaceuticals, cosmetics, and chemicals. These industries rely on efficient, high-quality filling systems to meet strict regulations and consumer expectations.

Understanding the components of a liquid filling line is crucial for manufacturers. It helps them optimize production processes, reduce errors, and increase operational efficiency.

A basic liquid fill production line includes several key machines that work together to streamline the filling process. Here’s a breakdown of the main components:

● Purpose: The liquid filling machine ensures precise dispensing of liquid products into containers.

● Types of Machines:

○ Volumetric Fillers: Measure liquid based on volume.

○ Gravimetric Fillers: Fill containers based on weight.

○ Piston Fillers: Use pistons to measure and dispense liquid.

● Key Features: Precision, speed, and adaptability to various container sizes and liquid viscosities.

● Benefits: Reduces human error, enhances productivity, and ensures consistency in every fill.

● Function: Seals containers with caps, preventing leakage or contamination.

● Types:

○ Screw Capping: Tightens screw-on caps.

○ Snap Capping: Secures snap-on caps.

○ Press-On Caps: Used for press-fit caps.

● Importance: Prevents tampering, maintains product integrity, and extends the shelf life.

● Benefits: Increases operational speed and ensures secure, tamper-evident packaging.

● Function: Automates the application of labels to filled containers.

● Types: Automatic and semi-automatic machines.

● Customization: Adjusts for different label sizes, shapes, and materials.

● Benefits: Ensures consistent labeling, reduces manual labor, and improves packaging aesthetics.

● Function: Moves products smoothly from one machine to the next along the production line.

● Types:

○ Belt Conveyors: Commonly used in low-speed lines.

○ Roller Conveyors: Used for heavier containers.

○ Chain Conveyors: Suitable for heavy-duty applications.

● Role in Integration: Ensures seamless operation and connects different parts of the production line.

● Benefits: Reduces downtime, minimizes product handling, and improves overall efficiency.

The components of a liquid fill production line work seamlessly to ensure an efficient and continuous flow of operations. Here’s how they integrate:

Component | Function |

Liquid Filling Machine | Fills containers with a precise amount of liquid, ensuring accuracy. |

Capping Machine | Seals containers after filling to prevent leakage and contamination. |

Labeling Machine | Applies labels to the containers for identification and branding. |

Conveyor System | Moves containers smoothly from one stage to the next, ensuring consistency. |

The synchronization between these components is crucial for maximum efficiency. A well-coordinated system ensures minimal downtime and consistent output. In a fully automated line, the machines work together seamlessly, from filling to capping to labeling, speeding up the process and reducing human error.

Every production line can be customized based on specific needs. Here’s how businesses can adjust their liquid fill line:

● Product Type: Different products require different filling methods. For example, a thin liquid may need a gravity filler, while a thicker substance may require a piston filler.

● Container Size: Machines can be adjusted to handle containers of varying sizes, from small vials to large bottles.

● Production Volume: High-volume productions need faster, more efficient machines, while smaller productions may prioritize flexibility.

When customizing your line, choose components that best fit your product and production goals. This ensures maximum efficiency and product quality.

A liquid fill production line offers many advantages for manufacturers looking to improve their production efficiency and maintain product quality. Here are some key benefits:

● Increased Efficiency: Automation significantly reduces the need for manual labor, speeding up the entire production process. The machines work faster and more consistently than manual methods.

● Consistency and Precision: A liquid fill production line ensures each container is filled and sealed accurately, reducing the risk of human error and ensuring every product meets the same standards.

● Scalability: As your business grows, a liquid fill production line can easily be adjusted to meet higher production volumes. It’s easy to add more machines or enhance the system for increased output.

● Compliance: Liquid fill production lines help businesses comply with strict industry regulations, such as FDA and GMP standards in pharmaceuticals and food. Automation also ensures higher consistency in meeting these standards.

While liquid fill production lines bring efficiency, they also come with some challenges. Understanding these challenges is key to maintaining smooth operations:

● Common Challenges: Manufacturers often face issues like clogging, inconsistent filling, and machine breakdowns. These problems can slow down production and affect the quality of the products.

● Troubleshooting Tips: To address common issues:

○ Check nozzles for blockages to prevent clogging.

○ Regularly calibrate machines to ensure consistent fills.

○ Inspect seals and gaskets to avoid leaks during the capping process.

● Preventive Maintenance: Regular maintenance is crucial. Clean machines regularly, lubricate moving parts, and monitor performance to prevent downtime. Performing routine checks ensures a longer lifespan for the machines and reduces unexpected breakdowns.

To ensure your liquid fill production line operates at peak efficiency, regular maintenance and proper care are essential. Here are some best practices for keeping your system running smoothly:

● Regular Cleaning and Sterilization of Machines: Clean machines are critical for maintaining hygiene and avoiding contamination. Regularly sanitize all parts that come into contact with liquids to meet industry standards, particularly in the food and pharmaceutical industries.

● Importance of Routine Inspections to Prevent Downtime: Schedule routine inspections to identify and fix any issues before they cause downtime. Check for signs of wear and tear, leaks, or malfunctioning parts to ensure continuous production.

● How to Train Employees to Handle Machinery and Troubleshoot Minor Issues: Proper employee training is vital. Teach operators how to use machines correctly, monitor performance, and troubleshoot minor issues. This reduces errors, improves efficiency, and helps avoid costly downtime.

Understanding the components of a liquid fill production line is essential for efficient operations. Manufacturers should assess their specific needs before setting up their production lines to ensure optimal performance.Automating the liquid filling process enhances efficiency, reduces errors, and ensures consistent product quality.

A: The essential components include liquid filling machines, capping machines, labeling machines, and conveyor systems. These work together to ensure efficient and accurate filling, sealing, and labeling of containers.

A: Liquid filling machines use precise control systems, pumps, and sensors to regulate the flow of liquid. These technologies ensure consistent fill volumes, minimizing errors and ensuring product quality.

A: Yes, liquid fill production lines are customizable to handle various container sizes. Adjustable filling nozzles, conveyor speeds, and machine configurations ensure compatibility with different container shapes and sizes.

A: Regular maintenance includes cleaning and sterilizing machines, inspecting components for wear and tear, and lubricating moving parts. Routine checks help prevent breakdowns and ensure smooth operation.

A: Automation reduces human error, speeds up the filling process, and ensures consistent quality. It allows machines to work in sync, increasing production speed while maintaining accuracy.