| Customization: | Available |

|---|---|

| After-sales Service: | Support |

| Warranty: | 12 Months |

| Availability: | |

|---|---|

| Quantity: | |

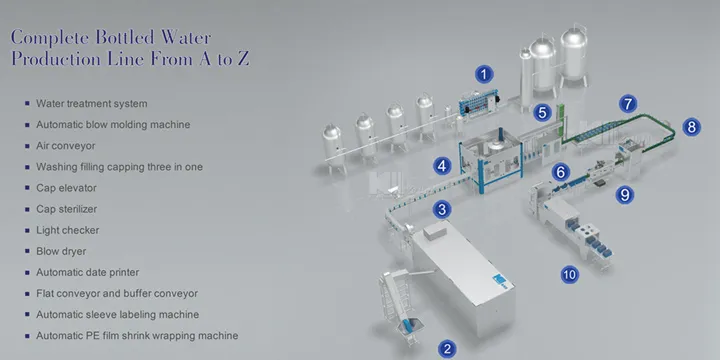

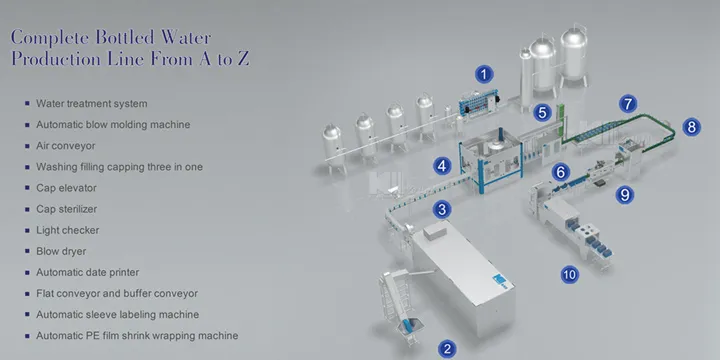

We supply complete solution for the water filling plant ,including Water treatment system / Washing filling capping machine / Code sprayer / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system

| Containers and specifications | |||||||

| Project Name: Full Automatic Complete Mineral Water 2000-20000bph Production Line | PH≥4.6drinking water | ||||||

| material | shape | Filling volume(ml) | Filling level(mm) | Neck type | |||

| PET Bottle | Square or Round Bottle | 100-2000ml | Distance from bottle neck According request | As request | |||

| Adjustable specifications of the bottle type | Middle Mould Base: Bottle diameter ≤105mm Bottle Height≤335mm | ||||||

| Customers need to buy additional change-over parts for the different bottles. If using square bottles, then bottle separating system will be added. | |||||||

| Container Label & Control Mode | Packaging system | Palletizing system | |||||

| Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic | Packing system | Min, Spec. | Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer | ||||

| Manual Film shrinker Wrap Around packer Robert Packing Machine | 1*2 2*3 3*4 4*6 3*5 | ||||||

| User Ambient Conditions: | Temperature:10~40ºC;Humidity:No dew | ||||||

| User Electrical Supply Specification | Voltage:380V±5%, 3phase; Frequency:50HZ±1% | ||||||

Our Water Bottling Line is tailored for beverage producers seeking efficient, reliable PET bottle filling systems. With a core capacity of 5000 bottles per hour (based on 500ml volumes), it accommodates a wide range of filling sizes—250ml, 330ml, 500ml, 1000ml, 1500ml, and 2000ml—making it flexible for diverse market needs. Every component adheres to food-grade standards, ensuring safe, hygienic production for mineral water, purified water, and spring water. As a one-stop solution provider, we integrate water treatment, filling, capping, labeling, and packing into a seamless workflow, reducing manual intervention and boosting operational efficiency.

Beyond equipment supply, we offer end-to-end support:

Pre-Sales: Customized line design based on your production space and output goals.

Installation: On-site technician deployment for equipment setup, debugging, and test production.

Training: Structured sessions on equipment operation, maintenance, and troubleshooting for your team.

After-Sales: 12-month warranty, free wear parts, and lifelong technical support.

This line is ideal for small to medium-sized water plants looking to scale efficiently while maintaining product quality and hygiene.

Production Capacity: 5000 bottles/hour (500ml PET bottles); adjustable for 250–2000ml volumes.

Bottle Compatibility: PET bottles (round or square); bottle diameter ≤105mm, bottle height ≤335mm (change-over parts required for different bottle types).

Core Material: SUS304 stainless steel (contact parts), ensuring corrosion resistance and compliance with food safety regulations.

Power & Environment: 380V±5% (3-phase), 50HZ±1%; operating temperature 10–40℃, humidity without dew.

Filling Accuracy: ±2‰, thanks to high-precision flowmeters on each filling valve, eliminating liquid waste and ensuring consistent product quality.

CGF8-8-3 Bottle Water Washing Filling Capping Machine,1,000-2,000 bottles per hour.

CGF14-12-4 Bottle Water Washing Filling Capping Machine, 2,000-3,000 bottles per hour.

CGF18-18-6 Bottle Water Washing Filling Capping Machine,6,000-7,000 bottles per hour.

CGF24-24-8 Bottle Water Washing Filling Capping Machine,8,000-9,000 bottles per hour.

CGF32-32-10 Bottle Water Washing Filling Capping Machine,10,000-12,000 bottles per hour.

CGF40-40-12 Bottle Water Washing Filling Capping Machine,12,000-15,000 bottles per hour.

| Project Name: | ||||||

| Model | CGF8-8-3 | CGF14-12-5 | CGF18-18-6 | CGF24-24-8 | CGF24-24-8 | CGF40-40-12 |

| Capacity | 2000 | 6000-8000 | 6000-8000 | 8000-12000 | 13000-15000 | 16000-18000 |

| Bottle shapes | PET circular or square | |||||

| Bottle diameter(mm) | Dia50-Dia115mm | |||||

| Bottle height (mm) | 160-320mm | |||||

| Compressor air pressure(Mpa) | 0.3-0.7Mpa | |||||

| Washing meidum | Aseptic water | |||||

| Rinsing pressure(Mpa) | >0.06Mpa <0.2mpa<> | |||||

| Application | drink water bottling production line | |||||

| Total power (KW) | 4.4 | 4.4 | 4.4 | 5.2 | 6.2 | 7.8 |

| Overall dimensions(L*W) | 2.3*1.9 | 2.5*1.9 | 2.8*2.15 | 3.1*2.5 | 3.8*2.8 | 4.5*3.3 |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.6m |

| Weight(kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg | 8000kg |

Detailed Photos

The rotary disk is fully made of SUS304 stainless steel.

Using imported special efficient spray nozzle, the washing water will be sprayed in a particular angle, can wash any part of the inner wall, rinse with water thoroughly and save flush bottle.

Bottle clamp and lifting mechanism of sliding sleeve adopts Germany Igus corrosion resistant bearing without maintenance.

Washing part moves by a frame in the transmission system through the gear transmission.

The filling machine is equipped with high precision flowmeter aboved each filling valve pipeline.

when the machine is designed , a parameter package is set on the electrical control system for each capacity.

each valve filling volume can be set through the touch screen, filling capacity accuracy can reached 2‰,

in the process of filling, filling valve and bottle neck do not contacvt , so filling process is very clean , without second pollution.

the filling valve opening and closing by cylinder which controlled by soleniod valve, the first rapid filling and stay for a while to certain amount and then switch to slow filling.

The capping machine is the highest precision in 3-in-1 unit machine, on the reliability of equipment operation, has enormous influence on the defective rate of the product.Introduced the world's most advanced Italian AROL capping machine technology, combining with the filling machine production experience improvement, and ask college of Shanghai Jiao Tong university mechanical engineering institute of electrical and mechanical design and automation technology of experts and professors to help design.

We provide the Complete plant turnkey project for pure water production line including:

| Technical parameter: Water bottling machine | ||||||

| Model | CGF8-8-3 | CGF14-12-4 | CGF18-18-6 | CGF24-24-6 | CGF32-32-8 | CGF40-40-10 |

| Capacity(for 500ml) | 2000 | 3000-4000 | 6000-8000 | 8000-12000 | 13000-15000 | 16000-18000 |

| Suitable bottle shapes | PET circular or square | |||||

| Bottle diameter(mm) | Dia50-Dia115mm | |||||

| Bottle height (mm) | 160-320mm | |||||

| Compressor air | 0.3-0.7MPa | |||||

| Washing meidium | Aseptic water | |||||

| Rinsing pressure | >0.06MPa <0.2mpa<> | |||||

| Application | Water bottling machine | |||||

| Total power (KW) | 4.4kw | 4.4kw | 4.4kw | 5.2kw | 6.2kw | 7.8kw |

| Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.6m |

| Weight(kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg | 8000kg |

| RO water treatment systemWe adopt different equipment to produce pure water, mineral water etc. The main equipment of RO Water Treatment Plant are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator, water tank etc. It can effectively get rid of muddy organic matter, iron, manganese etc, reduce the hardness of the water to make all specifications of the water quality fully meet the state fresh water standard of fresh drink water. |

Blow molding system1. Excellent Mechanical Strength, impact-resisting, and non-craking. | |

Automatic labeling machine1.Hot melt glue labeling machine is widely used for different material of container . | |

PE film packaging machineAutomatic PE film heat shrink wrapping machine is suitable for wrapping of such products as pop top, mineral water , bottles. beer, drinks etc. Working with PE film shrink tunnel to pack the goods perfectly , the whole production process adopts the Germany advanced technics, and the main parts are imported from international famous companies. It consists of seven actuating motor, through cooperation with 7 actuating motor to form the product packed with plastic film and several bottles as a group out from the hot shrinking packing machine. |

We supply complete solution for the water filling plant ,including Water treatment system / Washing filling capping machine / Code sprayer / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system

| Containers and specifications | |||||||

| Project Name: Full Automatic Complete Mineral Water 2000-20000bph Production Line | PH≥4.6drinking water | ||||||

| material | shape | Filling volume(ml) | Filling level(mm) | Neck type | |||

| PET Bottle | Square or Round Bottle | 100-2000ml | Distance from bottle neck According request | As request | |||

| Adjustable specifications of the bottle type | Middle Mould Base: Bottle diameter ≤105mm Bottle Height≤335mm | ||||||

| Customers need to buy additional change-over parts for the different bottles. If using square bottles, then bottle separating system will be added. | |||||||

| Container Label & Control Mode | Packaging system | Palletizing system | |||||

| Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic | Packing system | Min, Spec. | Manual Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer | ||||

| Manual Film shrinker Wrap Around packer Robert Packing Machine | 1*2 2*3 3*4 4*6 3*5 | ||||||

| User Ambient Conditions: | Temperature:10~40ºC;Humidity:No dew | ||||||

| User Electrical Supply Specification | Voltage:380V±5%, 3phase; Frequency:50HZ±1% | ||||||

Our Water Bottling Line is tailored for beverage producers seeking efficient, reliable PET bottle filling systems. With a core capacity of 5000 bottles per hour (based on 500ml volumes), it accommodates a wide range of filling sizes—250ml, 330ml, 500ml, 1000ml, 1500ml, and 2000ml—making it flexible for diverse market needs. Every component adheres to food-grade standards, ensuring safe, hygienic production for mineral water, purified water, and spring water. As a one-stop solution provider, we integrate water treatment, filling, capping, labeling, and packing into a seamless workflow, reducing manual intervention and boosting operational efficiency.

Beyond equipment supply, we offer end-to-end support:

Pre-Sales: Customized line design based on your production space and output goals.

Installation: On-site technician deployment for equipment setup, debugging, and test production.

Training: Structured sessions on equipment operation, maintenance, and troubleshooting for your team.

After-Sales: 12-month warranty, free wear parts, and lifelong technical support.

This line is ideal for small to medium-sized water plants looking to scale efficiently while maintaining product quality and hygiene.

Production Capacity: 5000 bottles/hour (500ml PET bottles); adjustable for 250–2000ml volumes.

Bottle Compatibility: PET bottles (round or square); bottle diameter ≤105mm, bottle height ≤335mm (change-over parts required for different bottle types).

Core Material: SUS304 stainless steel (contact parts), ensuring corrosion resistance and compliance with food safety regulations.

Power & Environment: 380V±5% (3-phase), 50HZ±1%; operating temperature 10–40℃, humidity without dew.

Filling Accuracy: ±2‰, thanks to high-precision flowmeters on each filling valve, eliminating liquid waste and ensuring consistent product quality.

CGF8-8-3 Bottle Water Washing Filling Capping Machine,1,000-2,000 bottles per hour.

CGF14-12-4 Bottle Water Washing Filling Capping Machine, 2,000-3,000 bottles per hour.

CGF18-18-6 Bottle Water Washing Filling Capping Machine,6,000-7,000 bottles per hour.

CGF24-24-8 Bottle Water Washing Filling Capping Machine,8,000-9,000 bottles per hour.

CGF32-32-10 Bottle Water Washing Filling Capping Machine,10,000-12,000 bottles per hour.

CGF40-40-12 Bottle Water Washing Filling Capping Machine,12,000-15,000 bottles per hour.

| Project Name: | ||||||

| Model | CGF8-8-3 | CGF14-12-5 | CGF18-18-6 | CGF24-24-8 | CGF24-24-8 | CGF40-40-12 |

| Capacity | 2000 | 6000-8000 | 6000-8000 | 8000-12000 | 13000-15000 | 16000-18000 |

| Bottle shapes | PET circular or square | |||||

| Bottle diameter(mm) | Dia50-Dia115mm | |||||

| Bottle height (mm) | 160-320mm | |||||

| Compressor air pressure(Mpa) | 0.3-0.7Mpa | |||||

| Washing meidum | Aseptic water | |||||

| Rinsing pressure(Mpa) | >0.06Mpa <0.2mpa<> | |||||

| Application | drink water bottling production line | |||||

| Total power (KW) | 4.4 | 4.4 | 4.4 | 5.2 | 6.2 | 7.8 |

| Overall dimensions(L*W) | 2.3*1.9 | 2.5*1.9 | 2.8*2.15 | 3.1*2.5 | 3.8*2.8 | 4.5*3.3 |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.6m |

| Weight(kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg | 8000kg |

Detailed Photos

The rotary disk is fully made of SUS304 stainless steel.

Using imported special efficient spray nozzle, the washing water will be sprayed in a particular angle, can wash any part of the inner wall, rinse with water thoroughly and save flush bottle.

Bottle clamp and lifting mechanism of sliding sleeve adopts Germany Igus corrosion resistant bearing without maintenance.

Washing part moves by a frame in the transmission system through the gear transmission.

The filling machine is equipped with high precision flowmeter aboved each filling valve pipeline.

when the machine is designed , a parameter package is set on the electrical control system for each capacity.

each valve filling volume can be set through the touch screen, filling capacity accuracy can reached 2‰,

in the process of filling, filling valve and bottle neck do not contacvt , so filling process is very clean , without second pollution.

the filling valve opening and closing by cylinder which controlled by soleniod valve, the first rapid filling and stay for a while to certain amount and then switch to slow filling.

The capping machine is the highest precision in 3-in-1 unit machine, on the reliability of equipment operation, has enormous influence on the defective rate of the product.Introduced the world's most advanced Italian AROL capping machine technology, combining with the filling machine production experience improvement, and ask college of Shanghai Jiao Tong university mechanical engineering institute of electrical and mechanical design and automation technology of experts and professors to help design.

We provide the Complete plant turnkey project for pure water production line including:

| Technical parameter: Water bottling machine | ||||||

| Model | CGF8-8-3 | CGF14-12-4 | CGF18-18-6 | CGF24-24-6 | CGF32-32-8 | CGF40-40-10 |

| Capacity(for 500ml) | 2000 | 3000-4000 | 6000-8000 | 8000-12000 | 13000-15000 | 16000-18000 |

| Suitable bottle shapes | PET circular or square | |||||

| Bottle diameter(mm) | Dia50-Dia115mm | |||||

| Bottle height (mm) | 160-320mm | |||||

| Compressor air | 0.3-0.7MPa | |||||

| Washing meidium | Aseptic water | |||||

| Rinsing pressure | >0.06MPa <0.2mpa<> | |||||

| Application | Water bottling machine | |||||

| Total power (KW) | 4.4kw | 4.4kw | 4.4kw | 5.2kw | 6.2kw | 7.8kw |

| Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.6m |

| Weight(kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg | 8000kg |

| RO water treatment systemWe adopt different equipment to produce pure water, mineral water etc. The main equipment of RO Water Treatment Plant are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator, water tank etc. It can effectively get rid of muddy organic matter, iron, manganese etc, reduce the hardness of the water to make all specifications of the water quality fully meet the state fresh water standard of fresh drink water. |

Blow molding system1. Excellent Mechanical Strength, impact-resisting, and non-craking. | |

Automatic labeling machine1.Hot melt glue labeling machine is widely used for different material of container . | |

PE film packaging machineAutomatic PE film heat shrink wrapping machine is suitable for wrapping of such products as pop top, mineral water , bottles. beer, drinks etc. Working with PE film shrink tunnel to pack the goods perfectly , the whole production process adopts the Germany advanced technics, and the main parts are imported from international famous companies. It consists of seven actuating motor, through cooperation with 7 actuating motor to form the product packed with plastic film and several bottles as a group out from the hot shrinking packing machine. |