Views: 0 Author: Site Editor Publish Time: 2025-05-30 Origin: Site

Are you still relying on manual filling methods? It might be time to consider automation. Automated can filling machines are transforming industries like food, beverage, and pharmaceuticals.

These machines boost production speed, ensure precise accuracy, and reduce labor costs. In this post, we'll explore the key advantages of automation and how it can improve your production process.

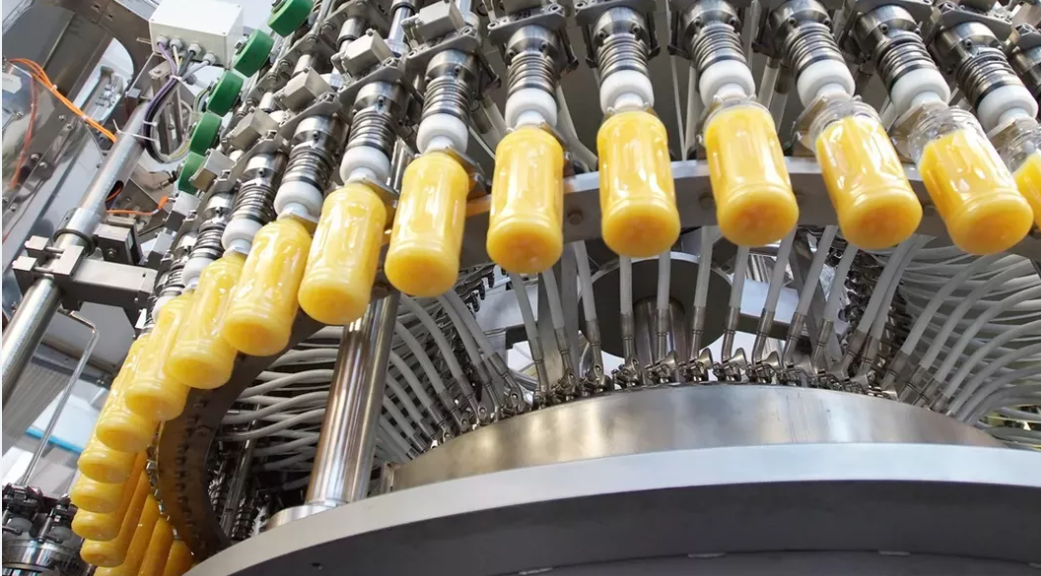

An automated can filling machine is a modern device used to fill liquids into cans or bottles. It's designed to make the filling process faster, more precise, and less reliant on human workers. This technology is essential for industries that require high-volume production with consistent quality.

Automated can filling machines use different systems depending on the liquid type:

● Vacuum Filling: This system uses suction to draw liquid into the cans, keeping air out. It's ideal for products like juices or wines, which are sensitive to oxygen.

● Gravity Filling: Liquids flow by gravity into the cans. This system works well for thin liquids such as water or soft drinks.

● Piston Filling: A piston mechanism pushes liquid into containers. It’s suitable for thicker liquids like sauces, syrups, or creams.

● Pressure Filling: This method uses pressure to maintain carbonation in beverages like soda or beer, preventing foam and ensuring the liquid is filled without spilling.

These machines can handle a wide range of liquids, including:

● Beverages: Water, juices, soda, beer, and other drinks.

● Food Products: Sauces, oils, syrups, and jams.

● Pharmaceuticals: Liquid medications, health supplements, and tonics.

● Cosmetics: Shampoos, conditioners, lotions, and creams.

They are adaptable to various viscosities and packaging needs, making them versatile for different industries.

Automated can filling machines are crucial for industries like:

● Food and Beverage: For filling drinks, oils, sauces, and other liquid food products.

● Pharmaceuticals: Used for filling medications and health-related liquids.

● Cosmetics: Essential in packaging cosmetic liquids such as lotions, gels, and shampoos.

● Chemicals: Fillers for cleaning products, oils, and industrial liquids.

These machines consist of several essential components:

● Filling Nozzles: Directly dispense the liquid into the cans, ensuring precise measurements.

● Conveyor Belts: Move the containers through the system, keeping production continuous and efficient.

● Capping Mechanisms: Automatically seal the cans after filling to prevent contamination.

● Sensors: Monitor the filling process, ensuring accuracy and consistency in each can.

The filling process is controlled by advanced systems:

● PLC (Programmable Logic Controller): Manages and automates the machine's operation for smooth transitions between processes.

● Touch Screens: Operators use them to adjust settings like fill volume and speed, making the system user-friendly.

● Sensors: Provide real-time data on fill levels, speed, and machine performance, ensuring quality control throughout the production cycle.

Automated can filling machines drastically increase production speed. These machines can fill hundreds or even thousands of cans per hour, far surpassing the capabilities of manual filling. In comparison, manual methods are much slower and prone to inefficiencies.

Thanks to their high throughput, automated machines can keep up with high demand, meeting production quotas without delays. This increased speed helps manufacturers stay competitive and meet tight deadlines.

Automation speeds up the entire production process. With automated filling machines, there’s less time spent on manual adjustments or constant monitoring. Machines run continuously, only needing minor adjustments when necessary, freeing up employees to focus on other important tasks. This time-saving feature not only improves efficiency but also reduces labor costs.

One of the key advantages of automated can filling machines is their ability to ensure precise fill levels. These machines are equipped with sophisticated systems that guarantee each can is filled with the exact amount of liquid, preventing issues like overfilling or underfilling. This level of accuracy is vital for maintaining consistency in the product, which leads to higher customer satisfaction.

Manual filling processes are highly susceptible to human error. Workers might accidentally overfill or underfill cans, or even contaminate the product. Automated machines eliminate these risks by precisely controlling the filling process. This leads to fewer mistakes, ensuring that the quality of the product remains consistent and the production process stays efficient.

Automated can filling machines reduce the need for manual labor. With machines handling the bulk of the work, fewer workers are needed on the production line. This means significant cost savings on wages and labor expenses.

Additionally, automation minimizes the need for constant supervision, as the machines are designed to run continuously with minimal intervention.

By automating the filling process, businesses can redirect their workforce to more important tasks. Instead of spending time on repetitive filling tasks, workers can focus on areas like quality control, maintenance, or packaging.

This shift allows companies to make better use of their labor resources, improving overall efficiency and adding value to the production process.

Automated can filling machines are designed to handle a wide range of liquid products. They can efficiently fill both thin liquids, like water and soft drinks, and thicker products such as sauces, oils, or creams.

These machines are equipped to adjust to different viscosities, ensuring accurate and consistent filling regardless of the product’s thickness or consistency. Whether it's beverages, pharmaceuticals, or food items, these machines can meet the diverse needs of various industries.

These machines are also highly versatile when it comes to container sizes and shapes. They can fill small bottles, large cans, or even pouches, making them ideal for businesses with diverse packaging needs.

Thanks to quick changeovers, automated can filling machines can easily switch between different packaging formats. This adaptability reduces downtime, allowing for smooth transitions between various product lines.

In industries like food and beverage, compliance with safety and health regulations is crucial. Companies must adhere to strict guidelines to ensure the safety and quality of their products. Automated can filling machines are built to meet these regulations, including hygiene and product safety standards.

For example, they help manufacturers comply with Good Manufacturing Practices (GMP) and FDA regulations, ensuring that products are handled, filled, and sealed safely. Automation guarantees consistency, which is essential for meeting these standards.

Automation significantly reduces the risk of contamination during the filling process. These machines are designed with sanitary features, like stainless steel components and sealed systems, to prevent any external contaminants from entering the product.

By minimizing human contact with the product, automation helps maintain the highest hygiene standards. This ensures that products, especially in the food, beverage, and pharmaceutical industries, remain safe for consumption and free from contamination.

While automated can filling machines require a significant initial investment, the long-term benefits far outweigh the costs. The higher upfront price is balanced by the substantial savings in labor and operational efficiency over time. With automation, companies reduce their reliance on manual labor, cutting down on wages and associated costs.

Moreover, these machines help reduce waste by ensuring accurate fill levels, which means fewer resources are wasted. Over time, the return on investment (ROI) becomes evident as production costs decrease.

Modern automated can filling machines are designed with energy efficiency in mind. These machines use less power, resulting in reduced energy costs, which can significantly lower operational expenses over time.

Additionally, the automated systems are built with high-quality materials, leading to lower maintenance costs. The machines are durable and require less frequent servicing compared to older, manual systems, making them a more cost-effective solution in the long run.

Industry 4.0 is revolutionizing automated can filling technology. IoT (Internet of Things) integration allows machines to connect, providing real-time monitoring and data collection. This enables predictive maintenance, where the machine can alert operators about potential issues before they occur, reducing downtime and maintenance costs.

The future of filling machines will rely heavily on connected systems. These systems will provide more in-depth performance analytics, offering manufacturers insights to optimize production processes and increase efficiency.

As sustainability becomes more important, automated can filling machines are evolving to incorporate energy-saving technologies. Many machines now use efficient motors and systems designed to minimize power consumption. This not only reduces operational costs but also helps businesses meet their sustainability goals.

Automation also plays a key role in waste reduction. By ensuring precise filling and reducing overfilling or underfilling, these machines minimize product waste, which in turn decreases the environmental footprint. With better resource management, companies can contribute to greener, more sustainable production processes.

When selecting an automated can filling machine, it’s crucial to assess your production needs. Consider factors like fill volumes, speed, and production capacity. Does your business need to fill large quantities of product quickly? If so, look for machines designed for high throughput.

You'll also need to determine the specific volume of each container to ensure the machine can handle it accurately. High-speed machines are ideal for large-scale production, while smaller operations might prioritize flexibility over speed.

Automated can filling machines vary in their ability to handle different types of liquids. When choosing a machine, it’s essential to consider what kind of liquids you’ll be filling. For example:

● Thin liquids like water or soda require a gravity filling system.

● Viscous liquids like sauces or creams need a piston filling system.

● Carbonated drinks require pressure filling to prevent foaming.

Selecting a machine designed for the right liquid type ensures smooth operation and avoids issues with product consistency.

Maintenance is another important factor when choosing the right machine. Look for machines that are easy to clean and maintain. Machines with modular designs are often easier to service and repair, reducing downtime.

It's also important to prioritize operational efficiency. Machines that require minimal supervision and are simple to operate will save you time and reduce training costs. Choose a machine that balances user-friendliness and high performance to minimize operational disruptions.

Automated can filling machines offer key advantages, such as increased efficiency, reduced labor costs, improved product quality, and adaptability. These benefits make them indispensable in industries like food, beverage, and pharmaceuticals. Investing in automation helps businesses stay competitive in a rapidly evolving market, future-proofing production processes for long-term success.

A: An automated can filling machine is a device that fills cans or bottles with liquid products using automated systems. It reduces manual labor and ensures consistent, efficient filling.

A: These machines use systems like gravity, piston, pressure, or vacuum filling to accurately dispense liquids into containers, ensuring high-speed production and precise fill levels.

A: Common industries include food and beverage, pharmaceuticals, cosmetics, and chemicals. These machines cater to a wide range of liquid products, ensuring safety and efficiency.

A: Yes, modern automated can filling machines are designed with energy-saving features, reducing energy consumption and lowering operational costs.