| Customization: | Available |

|---|---|

| After-sales Service: | Support |

| Warranty: | 12 Months |

| Availability: | |

|---|---|

| Quantity: | |

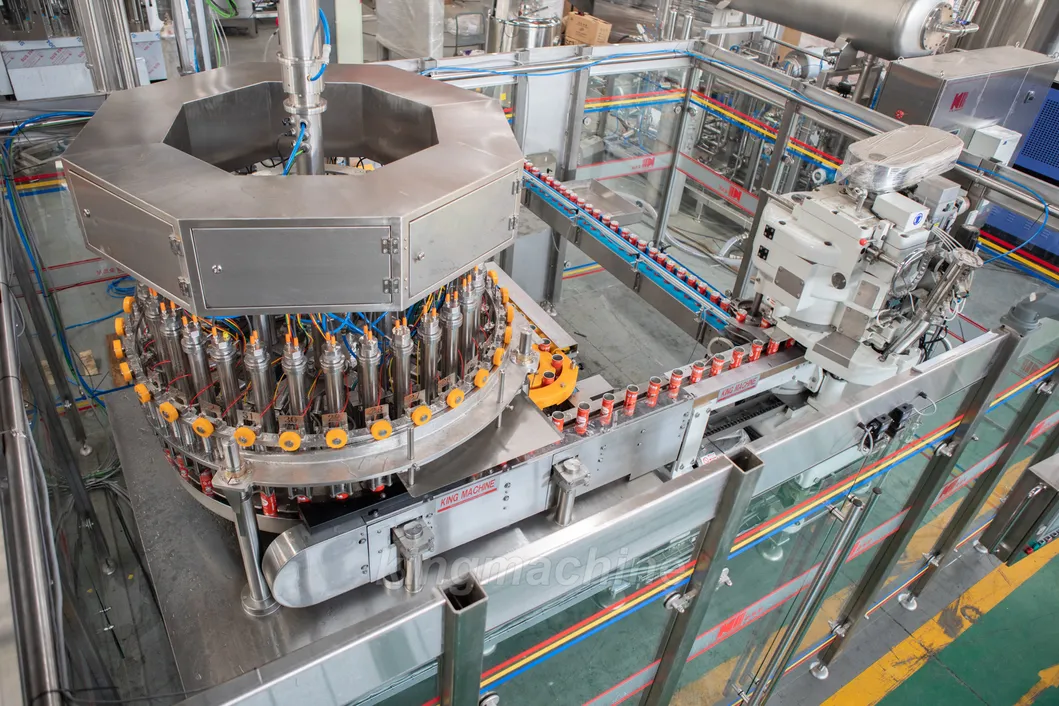

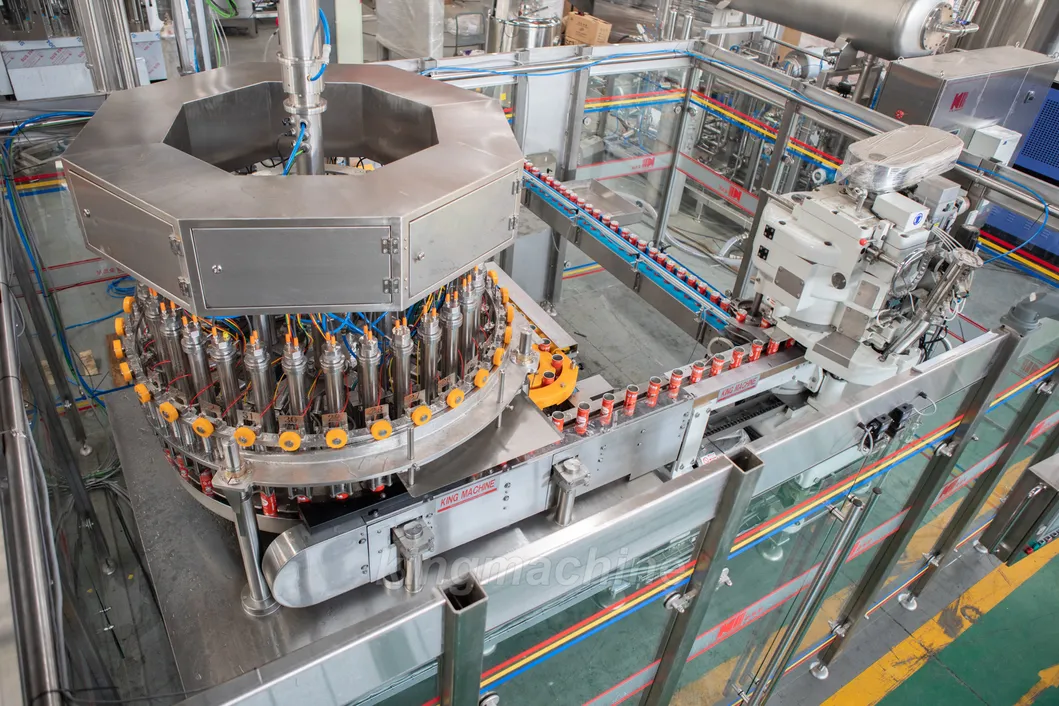

The Zip-Ton Can Filling Sealing Machine (Model: GDF) by King Machine is a fully automatic, rotary-type aluminum can filling and sealing solution designed for beverage production. As a core product from a leading Chinese manufacturer with nearly 15 years of expertise, this machine integrates advanced technology to handle a wide range of liquid products, ensuring efficiency, precision, and versatility for industrial-scale production.

Crafted from SUS 304 stainless steel, the machine meets strict hygiene standards, making it suitable for food and beverage applications. It supports a production capacity of 20-250 cph (cans per hour) across different models, with high-end variants reaching up to 60,000 cans/hour. Certified by CE, ISO, and SGS, it guarantees compliance with international quality and safety norms.

Beyond standalone functionality, the Zip-Ton series is part of a complete can packaging line, including auxiliary equipment like can depalletizers, rinsers, leakage checkers, liquid nitrogen dosing machines, and pasteurizer tunnels—providing a turnkey solution for carbonated drinks, beer, juice, and more.

Model | Capacity (cans/hour) | Suitable Can Specifications | Total Power | Overall Dimensions (L×W×H) | Weight |

GDF24-4 | 12,000 | Diameter: 50~99mm; Height: 70~175mm | 2.4kW | 2.5m×1.9m×2.3m | 2,500kg |

GDF32-4 | 15,000 | Diameter: 50~99mm; Height: 70~175mm | 4.4kW | 2.8m×1.9m×2.5m | 3,200kg |

GDF40-6 | 20,000 | Diameter: 50~99mm; Height: 70~175mm | 6.2kW | 3.5m×2.5m×2.5m | 4,500kg |

GDF54-6 | 30,000 | Diameter: 50~99mm; Height: 70~175mm | 7.2kW | 3.8m×2.8m×2.5m | 6,500kg |

GDF80-12 | 60,000 | Diameter: 50~99mm; Height: 70~175mm | 16kW | 3.8m×2.8m×2.5m | 10,000kg |

Equipped with float-ball cylinder volumetric filling technology and electronic control valves, the machine ensures exceptional accuracy with a filling difference of <±1ml (actual single-valve precision: ±0.5ml). Filling volume can be adjusted online without stopping production, maximizing operational efficiency.

A single machine handles multiple products, including still water, carbonated drinks, hot-filled juices, and beer—eliminating the need for separate equipment and reducing production line complexity.

The rotary structure, combined with star wheel conveyors and synchronized transmission systems, enables seamless can handling from rinsing to filling and sealing. It integrates with auxiliary systems like CIP (Clean-in-Place) circulation rinsing for easy maintenance and hygiene control.

Constructed from SUS 304 stainless steel, the machine resists corrosion and meets food-grade standards. It includes safety features such as overload protection and leakage detection, ensuring stable operation and product safety.

Optimized for low energy consumption, the machine reduces operational costs. Its modular design allows easy integration into existing production lines, minimizing setup time and investment.

The Zip-Ton Aluminum Can Filling Sealing Machine is widely used in the beverage industry, suitable for:

· Carbonated Soft Drinks (CSD): Soda, sparkling water, and flavored carbonated beverages.

· Alcoholic Beverages: Beer, cocktail, and wine (with compatible modifications).

· Non-Carbonated Drinks: Fruit juice, energy drinks, coconut water, and mineral water.

· Can Types: Aluminum cans, tin cans, and plastic cans (200ml to 500ml capacities).

It is ideal for small to large-scale production facilities, supporting complete lines from can depalletizing and rinsing to packaging (carton/film wrapping), making it a versatile choice for beverage manufacturers worldwide.

What is the warranty period?

The machine comes with a 12-month warranty, covering parts and labor.

Does it support overseas service?

Yes, King Machine provides on-site engineer support for installation, training, and maintenance overseas.

Can it be customized?

Customization is available for specific can sizes, production capacities, and product types.

What certifications does it hold?

It is certified by CE, ISO, and SGS, ensuring compliance with global industry standards.

The Zip-Ton Can Filling Sealing Machine (Model: GDF) by King Machine is a fully automatic, rotary-type aluminum can filling and sealing solution designed for beverage production. As a core product from a leading Chinese manufacturer with nearly 15 years of expertise, this machine integrates advanced technology to handle a wide range of liquid products, ensuring efficiency, precision, and versatility for industrial-scale production.

Crafted from SUS 304 stainless steel, the machine meets strict hygiene standards, making it suitable for food and beverage applications. It supports a production capacity of 20-250 cph (cans per hour) across different models, with high-end variants reaching up to 60,000 cans/hour. Certified by CE, ISO, and SGS, it guarantees compliance with international quality and safety norms.

Beyond standalone functionality, the Zip-Ton series is part of a complete can packaging line, including auxiliary equipment like can depalletizers, rinsers, leakage checkers, liquid nitrogen dosing machines, and pasteurizer tunnels—providing a turnkey solution for carbonated drinks, beer, juice, and more.

Model | Capacity (cans/hour) | Suitable Can Specifications | Total Power | Overall Dimensions (L×W×H) | Weight |

GDF24-4 | 12,000 | Diameter: 50~99mm; Height: 70~175mm | 2.4kW | 2.5m×1.9m×2.3m | 2,500kg |

GDF32-4 | 15,000 | Diameter: 50~99mm; Height: 70~175mm | 4.4kW | 2.8m×1.9m×2.5m | 3,200kg |

GDF40-6 | 20,000 | Diameter: 50~99mm; Height: 70~175mm | 6.2kW | 3.5m×2.5m×2.5m | 4,500kg |

GDF54-6 | 30,000 | Diameter: 50~99mm; Height: 70~175mm | 7.2kW | 3.8m×2.8m×2.5m | 6,500kg |

GDF80-12 | 60,000 | Diameter: 50~99mm; Height: 70~175mm | 16kW | 3.8m×2.8m×2.5m | 10,000kg |

Equipped with float-ball cylinder volumetric filling technology and electronic control valves, the machine ensures exceptional accuracy with a filling difference of <±1ml (actual single-valve precision: ±0.5ml). Filling volume can be adjusted online without stopping production, maximizing operational efficiency.

A single machine handles multiple products, including still water, carbonated drinks, hot-filled juices, and beer—eliminating the need for separate equipment and reducing production line complexity.

The rotary structure, combined with star wheel conveyors and synchronized transmission systems, enables seamless can handling from rinsing to filling and sealing. It integrates with auxiliary systems like CIP (Clean-in-Place) circulation rinsing for easy maintenance and hygiene control.

Constructed from SUS 304 stainless steel, the machine resists corrosion and meets food-grade standards. It includes safety features such as overload protection and leakage detection, ensuring stable operation and product safety.

Optimized for low energy consumption, the machine reduces operational costs. Its modular design allows easy integration into existing production lines, minimizing setup time and investment.

The Zip-Ton Aluminum Can Filling Sealing Machine is widely used in the beverage industry, suitable for:

· Carbonated Soft Drinks (CSD): Soda, sparkling water, and flavored carbonated beverages.

· Alcoholic Beverages: Beer, cocktail, and wine (with compatible modifications).

· Non-Carbonated Drinks: Fruit juice, energy drinks, coconut water, and mineral water.

· Can Types: Aluminum cans, tin cans, and plastic cans (200ml to 500ml capacities).

It is ideal for small to large-scale production facilities, supporting complete lines from can depalletizing and rinsing to packaging (carton/film wrapping), making it a versatile choice for beverage manufacturers worldwide.

What is the warranty period?

The machine comes with a 12-month warranty, covering parts and labor.

Does it support overseas service?

Yes, King Machine provides on-site engineer support for installation, training, and maintenance overseas.

Can it be customized?

Customization is available for specific can sizes, production capacities, and product types.

What certifications does it hold?

It is certified by CE, ISO, and SGS, ensuring compliance with global industry standards.